Banner Engineering has recently expanded its K50 product line of programmable indicators and touch and touchless buttons with new models now controllable via IO-Link and Modbus. These latest upgrades aim to enhance connectivity while enabling real-time control and increased flexibility in working with systems across various industrial settings.

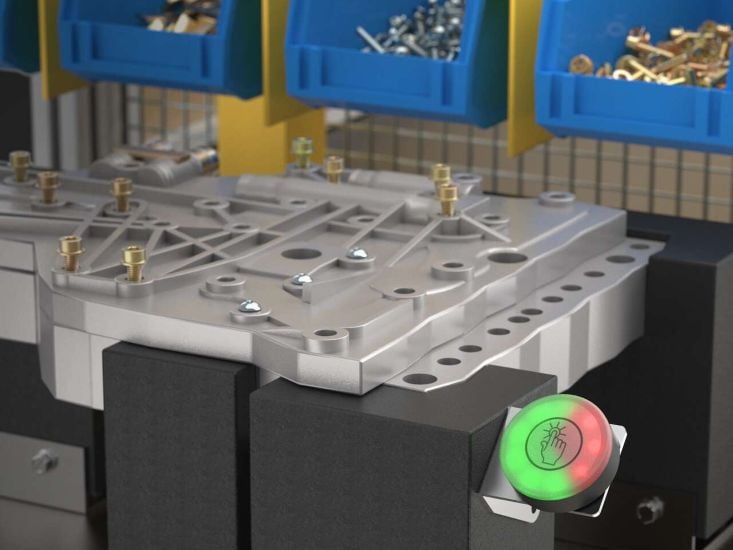

The latest programmable indicators and buttons in the K50 series are now controllable via IO-Link and Modbus. Image used courtesy of Banner Engineering

K50 Programmable Indicators and Buttons

The K50 programmable indicators and buttons offer bright and clear visual feedback in demanding environments, thanks to their 50 mm dome and compact housing. The design features models with 4-pin and 5-pin M12 connectors with a threaded M30 base, providing a plug-and-play interface for quick and easy installation.

Built for durability, the programmable indicators and buttons feature an IP66/IP67/1P69K-rated, lightweight design that can withstand impact, vibration, and moisture. Designed from FDA-approved materials, the K50 models meet standards for use in food and beverage production environments. The Pro audible variants are available with 14 different sound options that are useful in areas where auditory alerts are necessary.

The K50 touch and touchless buttons provide interactive control with feedback. Featuring advanced touch technology, the touch buttons enable reliable operation even when wearing gloves or exposed to water. On the other hand, the touchless models combine status indications with no-contact user interactions. The new IO-Link variants of the touchless buttons enable dynamic control over individual LEDs, providing access to sequence modes and enhanced visual feedback.

The K50 indicators and buttons can be configured with a variety of colors to indicate machine and system status. Image used courtesy of Banner Engineering

Controllable via IO-Link and Modbus

The new K50 programmable indicators and buttons from Banner feature expanded protocol support for IO-Link and Modbus integration, which includes Banner's PICK-IQ protocol, making the latest K50 models smarter with faster communication. The upgraded communication protocols enable easy device replacement with automatic loading of parameters via IO-Link, while Modbus enables high-speed data exchange in pick-to-light and operator guidance applications.

With the ability to display up to 14 different colors and 11 unique animation styles, the indicators offer customization options using the Pro Editor software from Banner or directly through Modbus and I/O link interfaces. With the software, users can fine-tune the LED sequences, alarm sounds, and response modes, ensuring an interaction tailored to the process logic.

Banner Engineering’s K50 programmable touch buttons can be operated via touch technology. Image used courtesy of Banner Engineering

Enhancing Lighting and Indication

Banner's latest K50 models are designed in response to the growing need for fast, clear, and actionable lighting and indication that guide operators, accelerate response times, and confirm the status of systems. With access to real-time process data and ease of setup, the new K50 models suit industries seeking a smarter, more responsive system that requires no additional hardware with minimal I/O wiring complexity.