Infineon Technologies and RT-Labs recently collaborated to integrate six key industrial communication protocols directly into the firmware of Infineon's XMC7000 industrial microcontroller.

The XMC7000 industrial MCU.

With the Industry 4.0 market projected to spike to $862B by 2032, it's more important than ever for industrial devices to support the top communication protocols in this space. Infineon and RT- to help developers use the MCU with these common protocols, including PROFINET RT, Ethernet/IP, CANopen, and Modbus. Infineon says this new integration simplifies the implementation of real-time industrial systems, reducing development time while improving reliability and compliance in factory automation, robotics, and control systems.

A Low-Power, High-Feature MCU

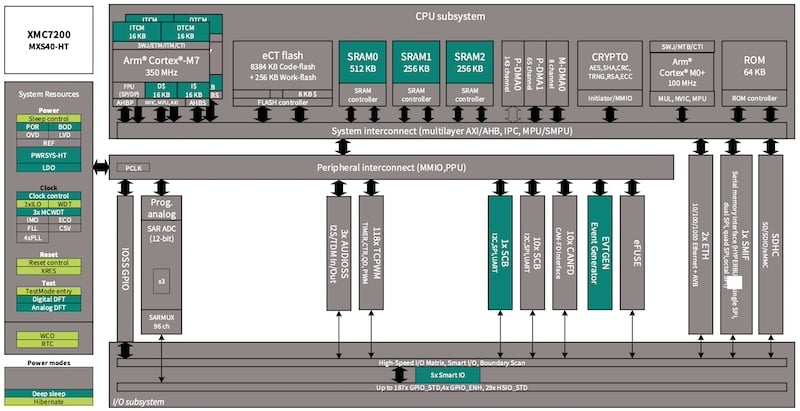

The XMC7000 series (datasheet linked) features single or dual Arm Cortex-M7 cores running up to 350 MHz, with an additional Cortex-M0+ core for auxiliary tasks. It includes up to 8 MB of Flash and 1 MB of RAM. The devices support 2.7 V to 5.5 V operation and function across a -40°C to 125°C temperature range for harsh environments.

Block diagram of the XMC7200.

Key peripherals include CAN FD, Gigabit Ethernet, and multiple timer modules, targeting applications like motor control, industrial drives, and factory automation. The XMC7000 architecture is built on a low-power 40-nm process technology. Importantly, it also has a cryptographic engine for enhanced hardware security.

A Unified Hardware Platform for Different Protocols

There are two benefits to the XMC7000's integration: first, firmware protocol support does not need to be built from scratch, and second, the same firmware (and hardware) already supports multiple protocols. Implementing industrial protocols for use with MCUs such as the XMC7000 has typically required developers to license or build protocol stacks separately, integrate them into the firmware, and ensure that they are compliant with industrial standards.

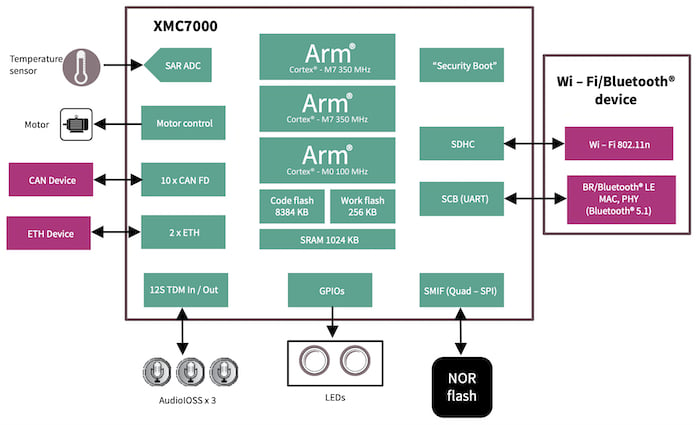

Application-level block diagram using XMC7000 MCU.

By integrating protocol stacks directly into the XMC7000 firmware, Infineon and RT-Labs remove these steps from the bring-up process. Developers working on industrial equipment—such as servo drives, PLCs, and I/O modules—can now enable communication protocols directly from ModusToolbox using pre-built middleware and code examples. This may accelerate the rapid development of real-time control systems, allowing teams to focus on application-level features instead of low-level communication challenges.

RT-Labs Leverages Its U-Phy Technology

Industrial systems often need to support different communication protocols depending on the application. This usually means developing multiple firmware variants or maintaining separate hardware platforms for each protocol. By integrating six widely used protocols into the firmware of a single MCU, Infineon and RT-Labs allow developers to meet a range of connectivity requirements without changing hardware. The approach aims to reduce engineering effort by turning protocol support into a configuration step rather than a full integration task. RT-Labs' U-Phy technology enables this unification.

U-Phy manages the physical interface layer behind the scenes. Developers can access protocol middleware through GitHub, configure their setup in ModbusToolbox, and move quickly from prototype to deployment. For many teams, this could simplify the path to compliance while cutting down on development time and cost.

Other Unified Platforms Available

Infineon and RT-Labs aren't the only ones providing such a unified approach. Companies like STMicroelectronics and NXP likewise offer integrated microcontroller platforms that bundle protocol stacks, peripheral drivers, and real-time operating systems into a single development environment.

For instance, ST’s STM32Cube ecosystem provides everything from USB and CAN libraries to RTOS support. NXP’s MCUXpresso SDK integrates drivers for I2C, SPI, and Ethernet alongside middleware and FreeRTOS—all tightly coupled with their respective hardware.