Modern packaging lines handle a growing mix of thin pouches and elongated bags filled with powders, liquids, and other fill materials that shift unpredictably when lifted. These products can bend or sag under vacuum pressure, which makes them difficult to move without distortion. Many facilities try to compensate by adding multiple suction cups to share the load, but that approach increases tooling complexity and introduces more failure points.

The ZP3P-WJT series was developed to counter those common issues. Instead of relying on several small round cups, the new oval design stretches the gripping area across a longer surface. That broader contact helps stabilize flexible packages during transfer and reduces the tendency for the material to wrinkle or collapse. Optional attachments control deformation even further, giving operators a cleaner handling method for today’s lightweight packaging formats.

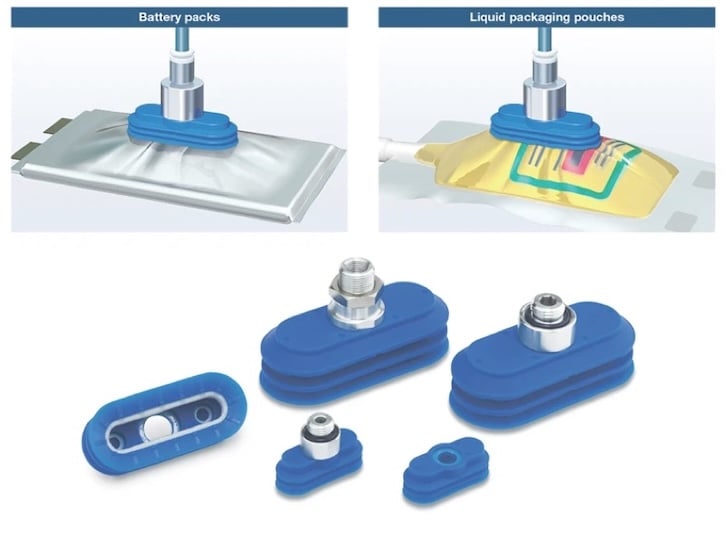

The oval cup maintains a steady seal on uneven or lightweight consumer packaging, adapting to film wrinkles and height variations during transfer. Image used courtesy of SMC

Designed for Challenging Packaged Workpieces

Standard suction cups tend to concentrate their force on a small spot, which works for rigid materials but becomes a problem when the item being lifted flexes or shifts the moment it leaves the conveyor. The elongated ZP3P-WJT cup helps spread that force more evenly, providing a steadier lift for packages that would otherwise fold or buckle. In many applications, a single oval cup does the work of two or three traditional cups, allowing the tooling to be simplified right away.

SMC offers two attachment styles to accommodate different packaging characteristics. One reduces cup deformation and is especially useful when handling thin or flexible films. The flat attachment works differently: it keeps the cup surface even, which helps smooth out wrinkles and maintain a consistent seal on materials that don’t sit perfectly flat.

Examples of the ZP3P-WJT oval bellows cups gripping flexible battery packs and liquid pouches. The extended contact area stabilizes thin, lightweight packaging during lifting. Image used courtesy of SMC

Compliant Materials for Food and Consumer Goods

The suction cup contains materials approved for food-contact use, which is essential for packaging operations where equipment may come into direct contact with bags or pouches. SMC also avoids oils, rust inhibitors, and similar treatments in the cup body. That choice minimizes the risk of residue transferring to products during handling.

Another small but important detail is the blue color. It’s intentional rather than aesthetic. If a cup begins to wear or if a fragment breaks off, the bright color is easy to spot during routine inspection. That visibility helps operators identify foreign material quickly, avoiding unnecessary downtime and keeping the process cleaner.

Reduced Equipment Complexity

Lines that move long or narrow packages often rely on several small suction cups arranged side by side. While that setup works, it adds weight to the end-of-arm tooling and increases the number of hoses, fittings, and spare parts required to keep the system running. Over time, these added components demand more maintenance and more attention from operators.

Switching to a single oval cup reduces much of that overhead. Vacuum routing becomes simpler, and mounting brackets no longer need to accommodate multiple contact points. Technicians also benefit from fewer wear parts to replace. Changeovers also become easier, since operators aren’t adjusting or aligning several cups every time the package size shifts.

Built for Clean, Consistent Performance

The bellows structure at the top of the cup gives it room to flex as packages move along the line. That flexibility helps maintain a steady seal even when products are slightly uneven, something that happens frequently with pouches filled with liquids or powders. Items that puff up after filling or flatten as they settle still remain securely gripped as the cup adapts to their shape. This ability to follow small variations becomes especially important on high-throughput equipment. Packages rarely arrive perfectly aligned or identical from one unit to the next. The ZP3P-WJT cup absorbs those inconsistencies naturally, preventing lost picks or dropped items during rapid transfer.

A Practical Option for Modern Packaging Equipment

The elongated shape of the cup aligns well with the form of many flexible packages. It supports more of the product without crushing or distorting the material, making it a strong fit for stick packs, slim bags, and similar formats. For machine builders and plant operators, the simpler tooling layout is another advantage. With fewer parts to manage, systems run cleaner and require less hands-on adjustment.

Ultimately, the ZP3P-WJT series offers a straightforward way to stabilize flexible packaged goods without redesigning entire gripper assemblies. It brings together compliance, stability, and reduced mechanical complexity, qualities that make it a practical upgrade for facilities adapting to the growing range of modern packaging materials.