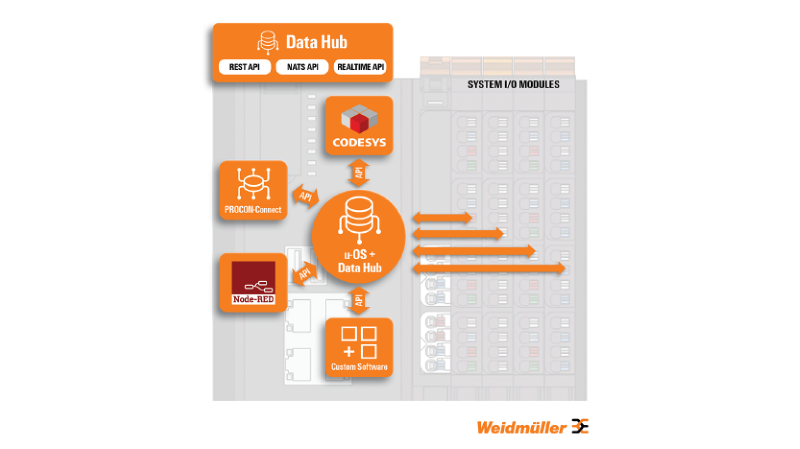

Industrial connectivity-focused company Weidmuller currently offers u-OS, an open operating system for edge computing in industrial automation applications. Recently, Weidmuller expanded its u-OS platform with Data Hub. The u-OS Data Hub is fully integrated into the u-OS operating system, offering integrators and machine builders a new way to exchange data.

Weidmuller’s new u-OS Data Hub is integrated into the company’s u-OS operating system for simplified data exchange. Image used courtesy of Weidmuller

u-OS Data Hub

Hardware is notorious for requiring manufacturer-specific software and communication protocols to be used with their brand. This adds costs because of licensing and the time required to install different software. Using an independent communication protocol that doesn't rely on any specific brand or protocol frees programmers and integrators to work on other tasks.

Weidmuller’s u-OS Data Hub is a new service for the company’s u-OS operating system that offers multiple ways to communicate with your edge hardware and retrieve collected data. At its core, Data Hub comprises three application programming interfaces (APIs). These APIs are open source and have been used in the web development industry for decades, so security is built into the protocol.

REST: This protocol is commonly used for retrieving data from web servers, so it makes sense to use the same technology to retrieve data.

NATS: A high-speed message protocol used for event-driven communications.

Real Time: When data is created, it sometimes needs to be analysed in real-time. This protocol uses a deterministic cyclic channel for exchanging data in real-time.

Weidmuller’s PAC controllers run the u-OS software for processing data locally. Image used courtesy of Weidmuller

Manufacture Independent Automation

Edge servers are a PC that reside at the edge of where data is created. In industrial automation, this would be in the control cabinet on the factory floor. By having data collection at the equipment, technicians and network administrators can build faster and more secure data collection systems. These servers run special software that utilizes industrial protocols and applications to interact with automation devices such as robots, servos, and analog sensors.

Exchanging data between applications is required when you want to analyze the data. An edge server may be unable to perform predictive maintenance algorithms, but a more powerful server that resides in an IT cabinet would, so the two systems need to exchange data securely and seamlessly.

By using REST or NATS, the two systems can exchange data without access to the core OS or the file system. Requests can be vetted to ensure that the predictive maintenance server is requesting data, not a malicious server.

Weidmuller’s u-OS Data Hub enables data exchange via REST, NATS, and REAL TIME APIs. Image used courtesy of Weidmuller

Simplifying Data Exchange

The industrial world is changing how we think about data collection. When computers were larger and more expensive, we would connect manufacturing equipment to the IT infrastructure within the plant and send all the data to those servers. This topology required integrators to work with the IT department and grant access to visitors and contractors.

With an edge server running Weidmuller’s u-OS software with the latest Data Hub service, IT and programmers can access data produced by the machine by simply sending a GET request to the edge server's IP address. The Data Hub service on the u-OS software allows integrators and machine builders to offer their customers the ability to access the data produced by the machine that makes their parts.