For automated systems, HMIs have become an essential component for real-time data exchange, intuitive control, and system interoperability. Featuring advanced visuals, robust construction, and a software ecosystem ready for cloud and IIoT integration, this HMI provides operators with ease of use as well as providing visuals to aid in troubleshooting or relaying crucial operational data.

Weintek has recently added the cMT3218XP 21.5” advanced HMI to their cMT X lineup. Image used courtesy of Weintek

Weintek has introduced the cMT3218XP, the latest addition to its cMT X Advanced Series. The HMI is designed to meet the growing demands of factories that are dabbling in automation. Combining a giant 21.5-inch Full HD display with a rugged aluminum enclosure, the cMT3218XP balances visual clarity, durability, and seamless integration for applications ranging from factory floors to digital kiosks.

Full HD Display with Wide Viewing Capability

The cMT3218XP features a 1920 × 1080 Full HD screen, delivering sharp, high-contrast visuals essential for monitoring control data, alarms, and system status. With a brightness of 500 cd/m² and a contrast ratio of 1000:1, the display remains clear even in brightly lit environments. WVA (Wide Viewing Angle) technology ensures consistent visibility up to 89° from all directions, ideal for shared workstations and dynamic production settings.

The cMT3218XP will feature consistent visibility from up to 89° from all directions. Image used courtesy of Weintek

Durable Build for Demanding Environments

Built to withstand harsh industrial conditions, the unit features a tempered glass capacitive touchscreen that supports multi-touch gestures and gloved operation. The IP66-rated front panel protects against dust and water ingress, while the NEMA 4-compliant aluminum housing resists vibration and mechanical stress. Weintek also includes flexible installation options, including panel mount and VESA, which allow the HMI to adapt easily across various machine types and enclosures.

Advanced Connectivity and Cloud Integration

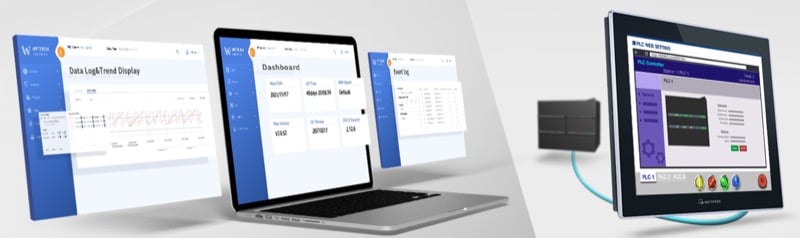

The cMT3218XP provides a central data hub that supports advanced key features for Industry 4.0, such as networking and modern integration capabilities. Users can access the HMI remotely via EasyWeb 2.0, while the built-in PLC Web Browser enables direct interaction with controller webpages. Monitoring options include VNC Viewer, WebView for browser-based access, and cMT Viewer for fast, independent multi-user monitoring.

The cMT3218XP will feature Weintek’s EasyWeb 2.0 and PLC web browser, providing integrators the tools they need for Industry 4.0 readiness. Image used courtesy of Weintek

For cloud connectivity, Weincloud delivers an integrated VPN and visualization dashboard that reduces the need for custom infrastructure. The unit also supports SQL database synchronization, OPC UA, Modbus TCP, and MQTT protocols, bridging the OT/IT divide with real-time, secure communication. JavaScript support will also enable developers to create custom functions and API connections, thereby expanding the use cases across automation networks.

Performance Built for Real-Time Automation

At its core, the HMI is powered by a quad-core RISC processor with 2GB of RAM and 4GB of flash storage, ensuring responsive performance and fast UI updates. The cMT3218XP will feature dual Ethernet, dual USB, RS-232, and RS-485 ports, offering flexible connectivity. Protocol support for MPI 187.5K and CANopen allows for integration into diverse automation ecosystems. The cMT3218XP can easily connect to a variety of PLCs, drives, and sensors from multiple vendors, enabling unified control and monitoring.

The cMT3218XP delivers an industrial-grade solution that merges clarity, speed, and resilience. Designed for engineers and system integrators focused on Industry 4.0 readiness, it simplifies operator interactions while enhancing data access and system reliability. With this release, Weintek continues to raise the standard for high-performance HMIs in advanced automation settings.