Typical additive manufacturing techniques, such as 3D printing, require many hours of tinkering. It is as much an art as it is a science to produce a functional design. This limitation, however, is being eroded away by current research at Washington State University. Instead of constantly adjusting and checking design parameters by hand, Kaiyan Qiu, Jana Doppa, and their team of researchers have leveraged the capabilities of artificial intelligence (AI) to print presurgical models of kidneys and prostates.

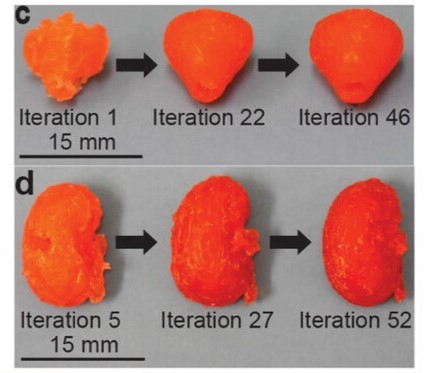

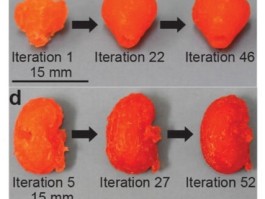

The progress of better models on prostate (top) and kidney (bottom) models. Image (modified) used courtesy of Advanced Materials Technology

Presurgical Organ Models

A presurgical organ model is a physical, three-dimensional replica of the organ that will be operated upon during surgery. Models are designed after actual data from CT scans, MRIs, and other techniques, mapping out the locations of veins, arteries, tumors, and other key features, making each model specific to an individual patient.

The purpose of the model is to help train the surgeon on how to work on this particular patient, as every person has differences in the physical locations of features in their organs. For vital organs, like kidneys, the surgeon can practice on multiple models before performing the surgery. Furthermore, they make a good training tool for medical students and for communicating to the patient exactly how their body has been affected and how the surgery can help.

Self-Improving Artificial Intelligence (AI)

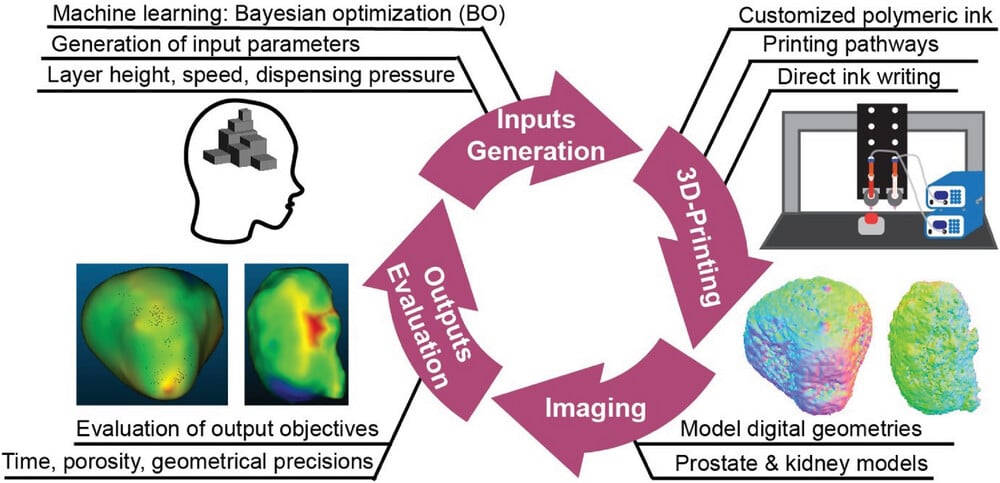

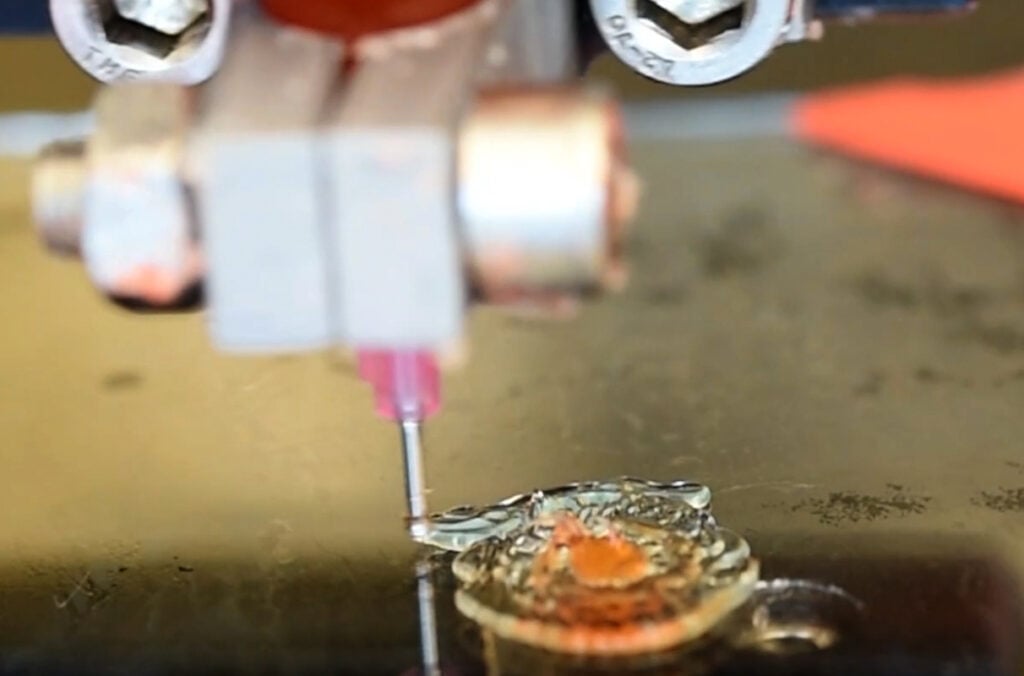

In the Washington State University research, AI-driven model improvements were made to a direct ink writing (DIW) 3D printer using a Bayesian Optimization method. In this optimization, important process parameters, such as nozzle velocity, dispensing pressure, layer height, etc., are automatically varied. Using machine vision and imaging, AI then measures or calculates critical metrics about the organ, such as porosity and geometric precision. The input process parameters are altered based on the data from these metrics. Through testing, more than 60 iterations were performed to print an optimized presurgical kidney and prostate model.

Washington State University researchers’ optimization and design process. Image used courtesy of Advanced Materials Technology

The drive for this project was not to directly produce kidney and prostate models, however. It was to prove the validity of using their Bayesian Optimization algorithm in a machine learning and AI-type environment. Once this methodology is verified, its application cases could be expanded to include other organ models and intricate parts used in manufacturing, like sensors and batteries.

Ultimately, the algorithm’s handling of the prostate model was better than that of the kidney model, but it does show that the methodology is sound. The algorithm can be adjusted slightly to improve the usability of the kidney model, perhaps by using additional inputs or figuring out why the changes between the later iterations did not alter the final design significantly.

The Bayesian Optimization AI technique could pave the way for 3D printing complex structures in medical applications and other crucial industries, like electronics and aerospace. Image used courtesy of Washington State University

3D Printing Complex Designs

In the not-so-distant future, data can be directly ported from the scanning equipment to the 3D printer, speeding up the process between detection of problems and the surgeon practicing for surgery, ultimately saving lives. Furthermore, as more of these models are produced, a database of similar features can be tracked. If a specific artery path through an organ eventually leads to blockage, perhaps this can be diagnosed and treated much more quickly, improving the patient's quality and duration of life.