The common view of 3D printing as a hobby for making small knick-knacks and playthings fails to recognize its significant influence in our everyday lives, such as in the medical field, the aerospace industry, or even in jewelry worn every day. Despite challenges regarding material properties and textures, there have been remarkable developments in the additive manufacturing process. This article will delve into two upcoming 3D printing techniques: speed-modulated ironing and holographic 3D printing.

By varying nozzle speed, researchers can control the amount of heat used to create varying textures and colors within a single print. Image used courtesy of Tech Xplore

Speed-Modulated Ironing

Researchers from MIT and Delft University of Technology have been working on a new technique for 3D printing called speed-modulated ironing. Essentially, this process uses a dual-nozzle 3D printer in which the first nozzle acts as a normal 3D printer by depositing a heat-responsive filament. Meanwhile, the second “ironing” nozzle passes over the printed material. When the ironing nozzle passes over the material, no more material is added, but the nozzle's speed is controlled to disperse heat to the heat-responsive material. This allows the material's color, shade, and roughness to be controlled and changed based on its properties.

With this 3D printing method, researchers from MIT and Delft have successfully demonstrated the capability to create items such as opaque water bottles at slower printing speeds and completely translucent objects at higher speeds. While the production rate may not be suitable for mass manufacturing of water bottles, the technology holds promise for efficient multimaterial 3D printing in industries such as aerospace and medicine. Researchers are also looking at this process to modify the mechanical and acoustic properties of thermally responsive materials, which could make 3D printing viable for even more industries.

Researchers demonstrate quicker and more efficient 3D printing of complex objects using ultrasonic sound waves. Image used courtesy of Tech Xplore

Holographic 3D Printing

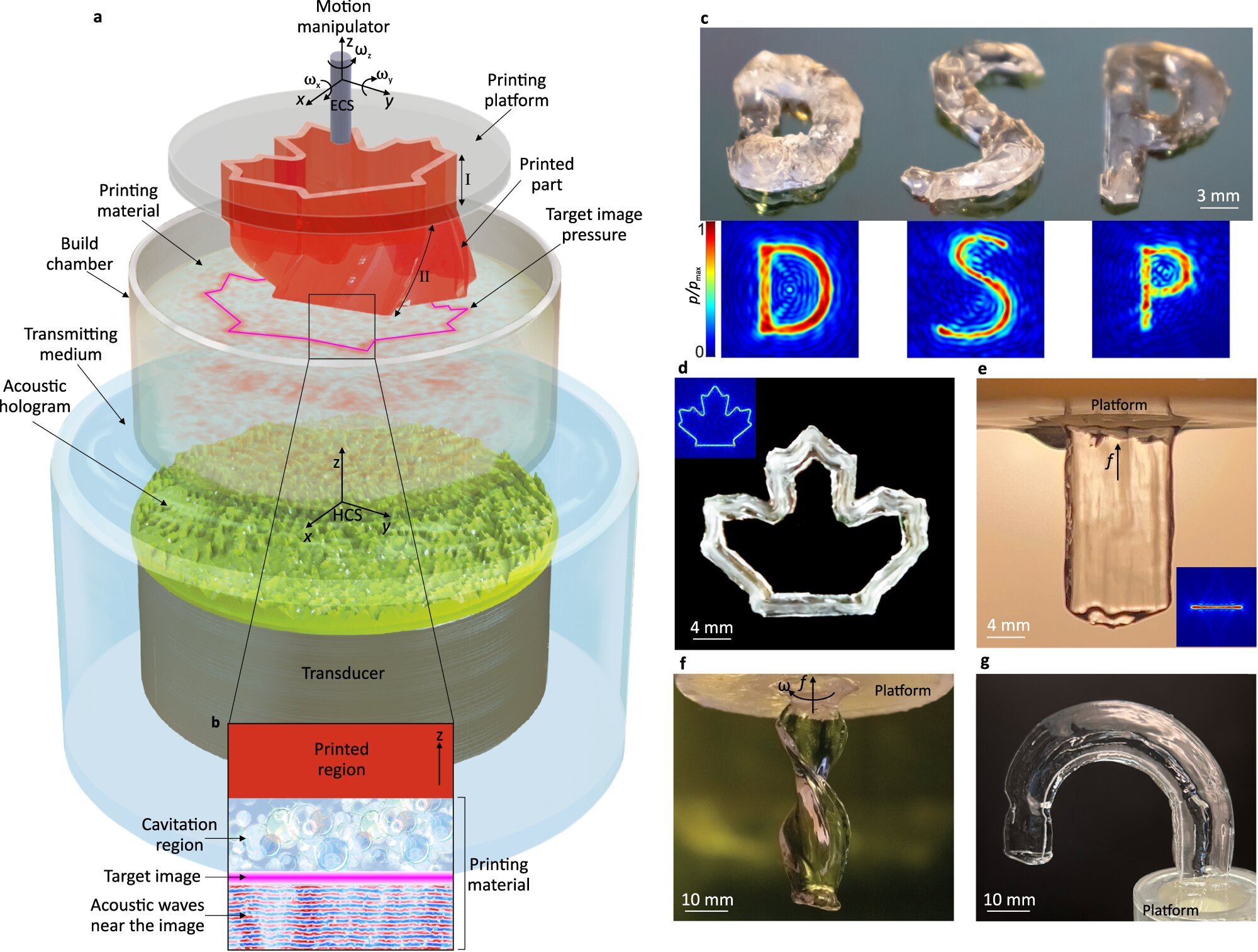

Concordia researchers are pioneering a method of 3D printing utilizing acoustic holograms, capable of achieving speeds up to twenty times faster than traditional 3D printers. This approach leverages holographic direct sound printing (HDSP), which uses sonochemical reactions to generate transiently high temperatures in localized "tiny bubble" regions, facilitating resin hardening.

Expanding on this foundation, the researchers have integrated this technique into acoustic holograms featuring cross-sectional areas of the 3D-printed design. When combined with a platform and a robotic arm operating according to a predefined algorithm, the result is a novel 3D printer resembling a standard resin printer but with significantly enhanced speed. Furthermore, the 3D printer enables real-time modifications to the 3D printed design during the printing process and facilitates the simultaneous printing of multiple objects at different locations within the same printing space.

Researchers are using “sound holograms” to 3D print at twenty times the speed of traditional methods. Video used courtesy of Concordia University

The holographic 3D printing harnesses soundwaves to create detailed and intricate structures, making it a promising technology with wide-ranging applications across multiple industries. The printing method holds particular promise for driving advancements in the medical field, enabling the fabrication of complex tissue structures, precise drug and cell delivery systems, and the production of skin grafts.