Although the Automate trade show is now several weeks past, our editorial engineering team got to meet with so many excellent companies and professionals that they deserve unique articles. Thanks for reading our Automate Highlight Series, and we look forward to seeing you again at a future show!

When industrial control manufacturers use the term edge, they are referring to the ability to process large amounts of data right inside the processor on the shop floor. Good ol’ PLCs have always been able to handle logic operations, timing, counting, and algorithms with perhaps the rolling average of an array. Still, they haven’t been up to the task of organizing and comparing large batches of production data values, or generating the motion path for a robot, or examining a photo to identify objects in real time.

These days, control is always on the hunt for better and more powerful technology. One of the highlights at Automate was the sheer number of controllers designed to elevate our perception of what’s possible: still handling the real-time machine logic with ease, but also adding the ability to store, transport, process, and ultimately, make better decisions with the mass of incoming data values.

Opto 22, a long-standing pioneer in industrial automation, invariably takes center stage with the groov EPIC Edge Programmable Industrial Controller, a robust (and might I say, fine-looking) controller that blends the real-time urgency of control with the ongoing influx of data.

The groov EPIC combines function with elegance to enhance control operations. Image used courtesy of Opto 22

Opto 22's participation at Automate, along with Inductive Automation and other partners, emphasized the power of open, integrated systems in tackling complex challenges that are demanded by modern industry. Proprietary systems have long been the established status quo of the industry, but this is changing thanks to open protocols and the interlinking support of companies with unique expertise, each contributing a piece of the necessary operation.

The groov EPIC

At the heart of the groov EPIC's appeal are numerous standout software and hardware features.

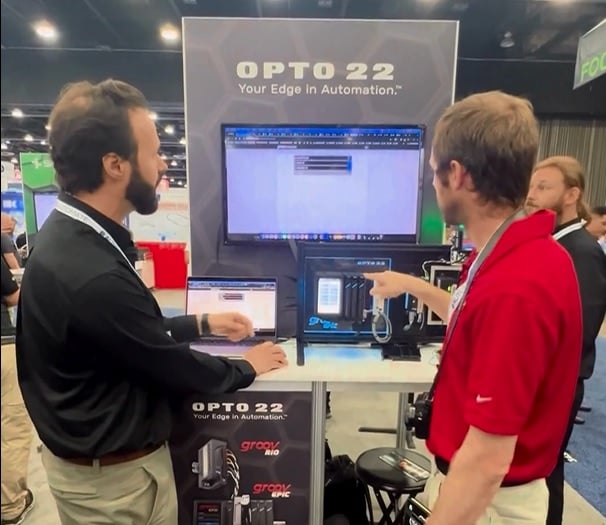

Listen to Opto 22’s Dan White explain the features of the groov Epic for Control.com’s Director of Engineering Content.

Open and Linux-based Architecture

Traditional PLCs use a runtime, an environment where no part of the program is developed, but rather the downloaded code is simply executed. In contrast, the groov EPIC runs a version of the Linux operating system. This provides tremendous flexibility for developers and engineers, allowing them to use increasingly familiar programming languages like Python or C/C++, alongside a traditional PLC environment (Opto 22’s own PAC Control and CODESYS being popular options).

Integrated Software

The groov EPIC comes pre-loaded with a powerful suite of software, making it a comprehensive solution right out of the box.

- PAC Control is Opto 22’s own traditional, flowchart-based control programming.

- The web-based visualization software, groov View, allows users to build and securely view operator interfaces from any authorized HMI device with a web browser, including the integrated high-resolution color touchscreen.

- Node-RED is a flowchart-based programming tool for connecting APIs, cloud applications, and databases, ensuring data connectivity between devices and application levels.

- Ignition Edge, a limited-featured version of Ignition made by Inductive Automation, is still a powerful module that provides OPC UA drivers for seamless connectivity to a wide range of PLCs, including Rockwell and Siemens, and supports IIoT protocols and packets like MQTT and Sparkplug. The integration with Ignition was a major part of the booth highlight, showcasing the partnership for bridging OT and IT.

Dan White (left) explains the web server configuration process to Control.com’s David Peterson (right).

- Security (for both the cyber and physical worlds) has been incorporated from the ground up. The hardware is resilient against a wide range of temperatures and environmental conditions. The dual, independent Gigabit Ethernet interfaces and cybersecurity features are the subject of constant, rigorous testing for compliance.

- Opto 22 also provides ongoing support for the entire catalog of products, including the I/O modules. These hot-swappable, high-density modules offer flexible configuration with precise data acquisition. You can also pull up module specs and wiring diagrams directly on the EPIC's touchscreen.

Here Today, Here Tomorrow

Demonstrations at trade shows can often only provide a brief snapshot of the true power of a flexible, reliable controller. Opto 22 provides a clear path to the industrial future by showing projects and case studies that underscore the device's ability to connect to legacy PLCs, process data at the edge, and publish it efficiently using IIoT methods. The partnership between Opto 22's hardware and Inductive Automation's software is a testament to the mindset of collaboration, not proprietary systems, driving the next generation of industrial automation.