Banner Engineering has launched wireless, battery-powered 3-axis vibration monitoring sensors designed to make predictive maintenance more practical and scalable. The new Q45VA3C and Q45VT3 models provide high-resolution vibration data without cabling or continuous power, detecting issues like bearing wear or misalignment before they lead to failure. With multi-year battery life, rugged IP67 housings, and seamless integration into Banner’s MultiHop wireless network, the system helps facilities expand condition monitoring to every critical machine.

The QM30VT3 detects possible bearing wear and pulley misalignment. Image used courtesy of Banner

Key Features and Specifications

At the heart of the system is true three-axis vibration sensing. Unlike two-axis or lower-quality MEMS sensors, where one axis can be noisy, the QM30VT3 platform captures ultra-low-noise data across the X, Y, and Z axes. This comprehensive view helps detect subtle problems such as angular misalignment, imbalance, or early bearing wear that may otherwise go unnoticed.

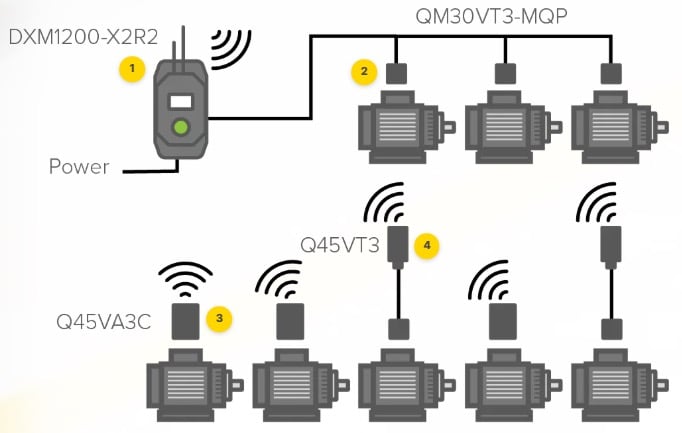

Two main configurations are available. The Q45VA3C is an all-in-one package that combines the sensor, radio, and C-cell battery into a rugged IP67-rated housing. It mounts quickly with magnets or epoxy and is suited for most rotating equipment. The Q45VT3, powered by a D-cell battery, connects via M12 cordset to a separate QM30VT3 sensor. This approach allows the sensor to sit directly on a motor or gearbox while the radio is mounted in a nearby location that's more accessible. Battery life also stands out as a practical advantage. The sensors use low-power operation to run for over two years on a single battery, and users can adjust reporting intervals to stretch that even longer. That means less time spent on maintenance while still getting the data when needed.

Advanced Monitoring Capabilities

Banner’s system does more than record vibration. Analysis features turn the readings into useful information. One of these, Adjustable Frequency Max (FMax), lets the user set the range to match machine speed. Higher values suit fast-rotating equipment, while lower values give better detail on slow-moving assets.

Another powerful tool is High-Frequency Enveloping (HFE), which filters out low-frequency signals and isolates high-frequency content. This makes it easier to catch early signs of bearing wear or lubrication breakdown, faults that can be difficult to identify in noisy environments. Combined with high-speed sampling rates up to 26.8 kHz, the sensors can capture short-duration impact events and subtle fault signatures before they escalate into major issues. For facilities that want predictive capabilities without building their own expertise, Banner’s line-powered QM30VT3 sensors also include VIBE-IQ, a machine learning feature that automatically sets baselines and thresholds.

Regulatory Considerations

Ease of integration is key in industrial environments where assets vary widely in size, age, and connectivity. Banner’s wireless devices are available in 900 MHz or 2.4 GHz models to ensure regional RF compatibility. Both versions easily link with the company’s MultiHop gateways, creating a unified network that can handle dozens of condition monitoring points.

The MultiHop gateway connects wireless sensors across the facility, enabling seamless vibration data collection and analysis. Image used courtesy of Banner

The IP67-rated housings withstand dust, oil, and washdown conditions, making them suitable for deployment in harsh environments such as consumable processing plants, outdoor installations, or heavy manufacturing floors. Combined with a two-year-plus battery life, the devices minimize the need for frequent intervention.

Broader Industry Impact

Banner’s wireless vibration monitoring opens the door for broader adoption of predictive maintenance by removing the need for hardwired connections and frequent servicing. Facilities can now place sensors on remote or hard-to-reach machines without running conduit or pulling power, greatly reducing installation costs. The impact stretches beyond convenience. With early detection of imbalance, misalignment, or bearing wear, operators can schedule maintenance during planned downtime rather than reacting to sudden failures. That shift saves money and increases safety by avoiding catastrophic breakdowns.

Maintenance teams are under constant pressure to cut downtime while dealing with larger and more complex fleets of machines. Banner’s wireless, battery-powered vibration sensors provide a straightforward option, with flexible placement, three-axis accuracy, and long battery life.