Engineers who understand the challenges of the packaging industry will instantly recognize the need for precision, speed, flexibility, and connectivity throughout control system architecture. In packaging lines, we find common applications of pneumatic and electric actuators that must coordinate motion and energy conservation in order to be competitive.

At PACK EXPO in Las Vegas, Camozzi Automation designed a booth that demonstrates elements of fluid power, linear actuation, and industrial network technologies coming together to enable more efficient packaging operations.

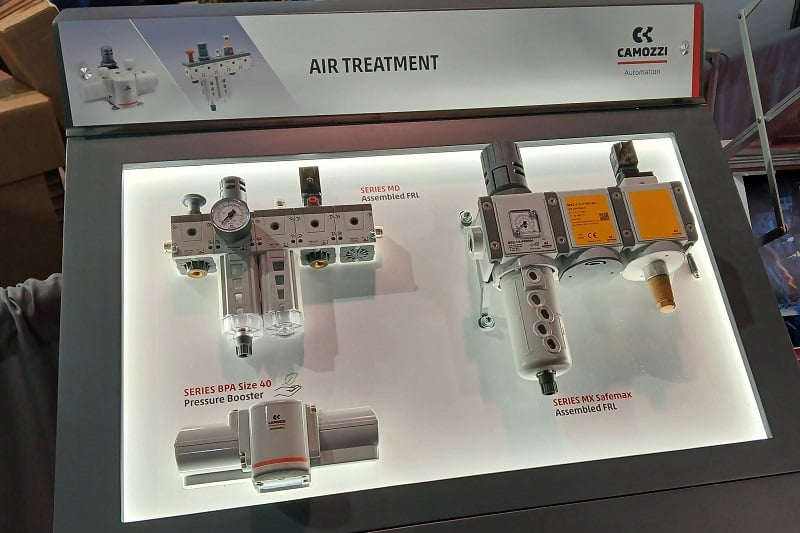

Pneumatic Control Devices

Even with the prevalence of electricity in automated facilities, pneumatics are still a dominant force in power delivery for actuators. For these systems, we consider not just the actuators, but the power units (compressors/pumps), the valves, the connectors, and the conditioning systems.

Camozzi exhibited its range of electromechanical cylinders and driver modules, along with proportional regulators and air treatment components, including pressure regulators, relief valves, and filtration systems, along with valve islands integrated with diagnostic software for predictive maintenance.

Camozzi’s range of pneumatic system treatment devices.

Electric Actuators

Not only does pneumatic technology deserve a spotlight, but there are many applications in which multi‑axis electric actuation can shine, showing how these electromechanical cylinders can often replace or augment pneumatic cylinders in high‑precision motions.

Camozzi demonstrated the DRVI field-oriented control (FOC) drive units sending commands to the electromechanical cylinder to show smooth, repeatable motion. This precision in control comes with a greater cost compared to pneumatic systems, but if the precise motion is required, Camozzi’s product catalog almost certainly contains the necessary specs.

Electric actuators and drive units.

Grippers also factor into the demo mix of motion electronics. Collaborative, angular, and parallel grippers, designed with both electric and pneumatic actuation, accomplish the ‘last mile’ of automation as the interface between the motion system and the product.

Communication and Networking

Fieldbus communication systems are another vital focus of modern industry. Camozzi emphasized its proportional regulators and valve islands, but these have limited functionality if we don’t consider the built‑in diagnostics and connectivity, allowing remote monitoring of system performance. Using predictive maintenance software tools, the system can track metrics such as valve cycle counts, pressure drops, and leak detection to ensure that the system remains in working order.

A machine demonstration with integrated actuators, drives, gripping systems, and communication devices.

Camozzi’s PACK EXPO demos, like so many others at this show and beyond, are designed to highlight the integration of modern industrial IoT or IIoT architectures into a more traditional display of motion and fluid control.

Camozzi Brings Motion to the Packaging Industry

Camozzi Automation’s PACK EXPO exhibit shows the future of packaging machinery as being more flexible in its use of motion technology - using both pneumatic and electric actuation. With a goal of becoming a global leader in automation, the offerings of smart grippers, electric motion modules, air treatment systems, and fieldbus devices provide a way to achieve that mission.

Product variation is increasing, standard batch sizes are continuously shrinking, and rigorous hygiene and sustainability demands continue to rise. Through all of this, Camozzi provided PACK EXPO attendees with ways to enable packaging equipment builders to meet those pressures with efficient, modern solutions.