Schneider Electric unveiled its newest distributed I/O system at the recent ProMat trade show in Chicago. The Modicon Edge I/O NTS has several new features and advantages that can help manufacturing facilities transition to a more future-proof automation system.

Modicon Edge I/O NTS

The Modicon Edge I/O NTS is a distributed I/O system with integrated data processing capabilities. Built for the ever-changing industrial landscape, this family of hardware combines all of the capabilities one would expect from an Industry 4.0 device, and adds some extended capabilities that will continue to be developed in the future.

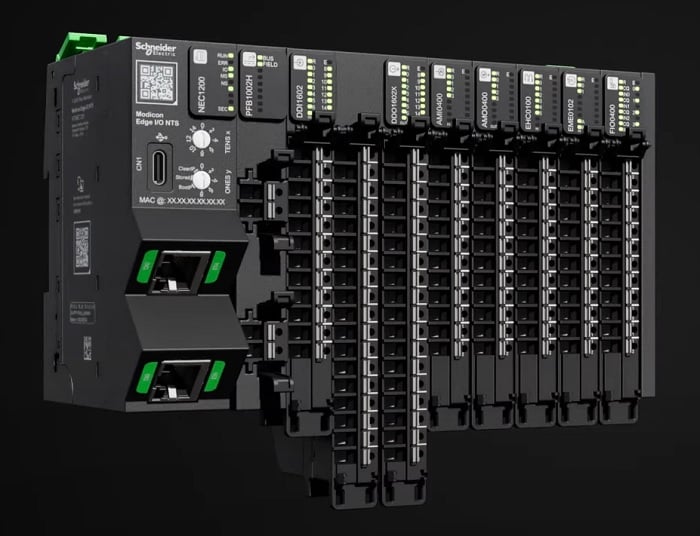

The new Modicon Edge I/O NTS. Image used courtesy of Schneider Electric

Craig Resnick, Vice President of the ARC Advisory Group, highlights a few of the forward-thinking developments and demands that will be required of new industrial hardware, such as “...data to support analytics, AI, virtualization, asset management, predictive maintenance, industrial internet of things (IIoT), digital twins and simulation, augmented and virtual reality, and the convergence of IT and OT.” All of these demanding applications require real-time, secure, reliable data, and Modicon can deliver.

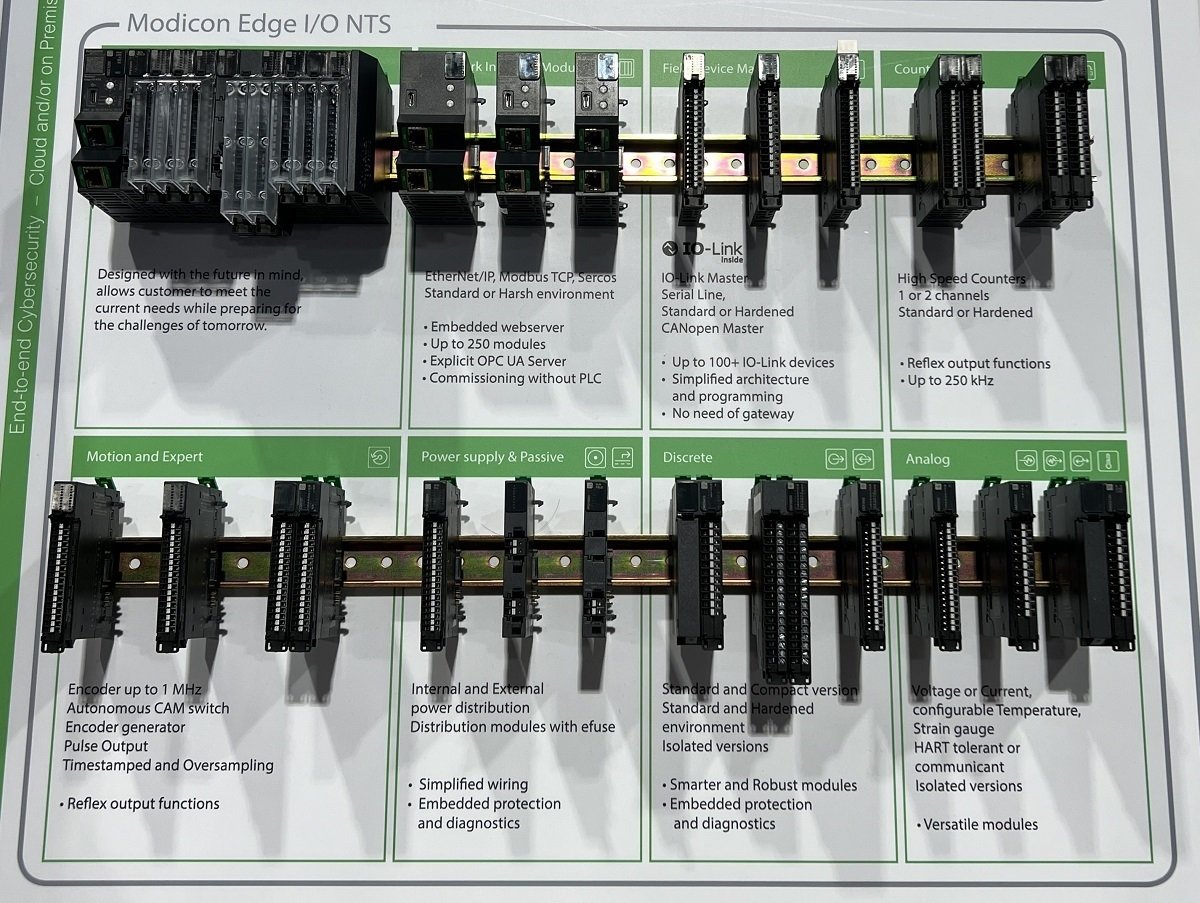

Schneider Electric offers a number of modules and accessories for the Modicon, such as for measuring pulse outputs, encoders, and other commonly used measurements. It can be linked to other devices over Ethernet/IP, Modbus TCP, or SERCOS, and has built-in diagnostics to save time in troubleshooting efforts.

Security of data and process control is enhanced by the use of OPC UA over Time Sensitive Networking (TSN). The OPC UA part allows for encryption, authentication, and data fidelity, while TSN provides more deterministic timing than other communication methods.

Control.com got to check out the extended lineup of Edge I/O NTS modules at the recent ProMat show in Chicago. Image used courtesy of Control.com

Key Features

The use of OPC UA over TSN makes the Modicon Edge allow for secure communication, as well as the flexibility to work with many existing communication protocols. It provides both security and flexibility. This is desirable over creating systems that must be “air gapped” or with components left disconnected from the rest to provide some isolation between potentially vulnerable equipment.

The bottom line: Modicon Edge I/O NTS will allow for secure, more deterministic data collection and supports real-time optimization of processes. With more data, costs are reduced through longer mean time between failures on equipment, optimization of predictive maintenance schedules, and other such data-driven decision-making processes. Furthermore, the enhanced security provided by the OPC UA will minimize the vulnerability of systems to ransomware and other crippling attacks.

Applications

The key features of the Modicon Edge I/O NTS will benefit most new automation systems or enhance existing ones. However, one of the key features of this upgrade is the enhanced security, raising its urgency from a simple “want” to a critical “need” for many manufacturing lines. With cyberattacks, particularly ransomware, on the rise, the ability to keep data and machines secure from bad actors has become increasingly important. With the Modicon Edge I/O NTS, security does not have to come at the cost of convenience and data portability.

Schneider Electric expects these benefits will be widely recognized in the mining, water and wastewater treatment, life sciences, chemical process industry, data centers, food and beverage manufacturing and other similar industries.