For many years now, servo motors have used a common safety protocol over the Ethernet topology to provide safe signals to safety functions. By using this safe communication protocol, machine builders have been able to shorten integration wiring time.

Recently, Dunkermotoren, a global supplier of large and small DC and AC motors along with linear systems, gearboxes, and encoders, has announced the release of dSafe for the BG75 and BG95 brushless DC motor series.

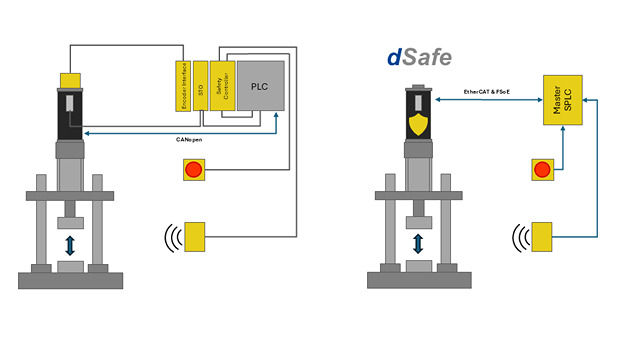

Dunkermotoren’s dSafe will be directly integrated into the BG75 and BG95 brushless DC motors. Image used courtesy of Dunkermotoren

Safety Functions for Drive Systems

A motor drive provides conditioned power to a motor as the PLC commands it, but there must be some safety systems in place to stop the motor in the event an operator enters the area. Functions like safe torque off (STO), safely limited speed (SLS), and safe stop (SS1) are some of the common safety functions you might find on a typical motor drive. These functions are commonly activated by wired signals from safety control systems.

Dunkermotoren’s latest dSafe technology is capable of executing these safety functions over a communication protocol such as FSoE or PROFIsafe. This eliminates the need for wiring safety outputs to drive systems and for troubleshooting the wiring or drive system when the functions fail to execute. Currently, dSafe is only available on Dunkermotoren’s BG75 and BG95 series of brushless DC motors.

With dSafe, users can avoid complex wiring that a traditional setup would require. Image used courtesy of Dunkermotoren

What Is Safely Limited Speed (SLS)?

When an application requires operators to interact closely with machinery, the SLS function enables motors to reduce their speed automatically. Typically, an area scanner is configured to scan for operators, and when detected, it will signal the motors in the area to reduce their speed. This reduced speed allows for an operator's or force sensor's reaction time.

What Are Safe Stop 1 (SS1) and Safe Torque Off (STO)?

Stopping a motor can be done in a couple of ways. You can cut off all power to the motor and apply the brakes right away, or you can signal to the motor to come to a stop safely. The latter method offers the least amount of wear on the motor. A safety output signal is used to command the motor to come to a halt in a controlled manner. Once the motor has come to a complete stop, the guard doors can be unlocked, and an operator can enter.

If your motor doesn’t have a safe stop function, then the control system must simply drop the STO signal, which causes the motor to stop uncontrollably, similar to slamming on the brakes of your car. Both functions are pivotal to stopping a motor and ensuring it is safe for an operator to enter the area.

Packaging machines with open concepts require advanced safety features to keep operators safe. Image used courtesy of Unsplash

Integrated Functional Safety

Dunkermotoren is staying competitive by offering its customers a more efficient way of issuing safety commands without the need for excessive wires. The dSafe technology aims to save commissioning and machinery build time. With the dSafe technology using the industry standard PROFIsafe and FSoE protocols, it can easily be integrated into new and existing systems.