There are many videos today showing a robot or gantry system 3D printing a large structure, such as a house or building. The principle of this technology is very similar to desktop 3D printers, only instead of using plastic, they are using concrete.

Recently, German 3D printing company COBOD, has announced a joint venture with Technische Universität Braunschweig to produce a commercially available multifunctional construction robot. The robot or gantry follows a computer-generated path and lays down layer after layer of a special type of concrete called shotcrete. Once complete, the robot is removed from the site, and a fully constructed structure remains.

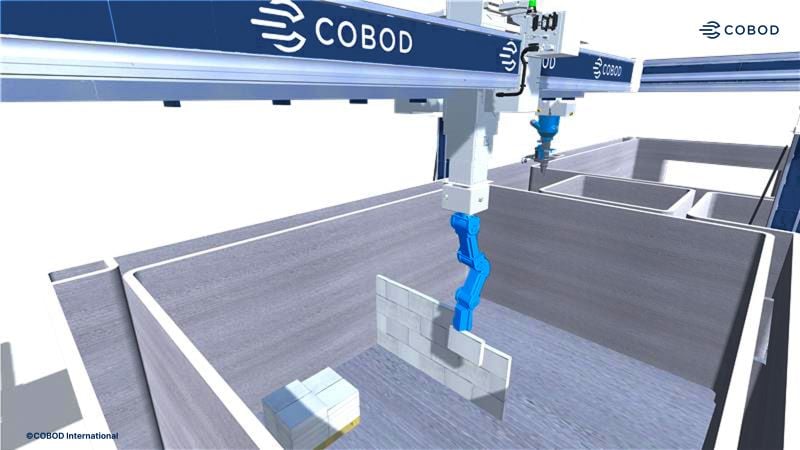

COBOD’s BOD2 3D gantry printer can print and spray concrete. Image used courtesy of COBOD

The BOD2 3D Gantry Printer

COBOD specializes in 3D printing structures for the construction industry. The company recently released a commercially available 3D printer and software that can design, mix, and print objects out of cement. The robotic system consists of a large gantry with a telescoping head and a robot arm attached to the head. The system is marketed as a multifunctional construction robot because the BOD2 is capable of mounting different tools to the vertical telescoping head, such as traditional grippers that can grip bricks or operate sanding tools.

The BOD2 Gantry 3D printer has a printing width of 14.62 m and a printing height of 8.54 m. Image used courtesy of COBOD

3D Printing Concrete

Any robot or 3D printer would be nothing without the software that tells the robot where to go. The BOD2 uses COBOD proprietary software that takes 3D CAD models and creates slices that are then converted into G-code. This software takes the place of a robot programmer and is designed to make the process much easier for the end user.

To 3D print an entire building, the gantry robot needs to engulf the entire job site, yet still be able to scale down for smaller jobs. The BOD2 has a max printing width of 14.62 m and a max printing height of 8.54 m. The length of the building can be as long as the customer wants, thanks to the modular steel truss structure.

CAD simulation of the BOD2 using a robot gripper to build a wall out of blocks. Image used courtesy of COBOD

3D Printing in Construction

3D printing a house or building is a great way to produce a building with limited staff and supplies quickly. The BOD2 is a system that can be set up speedily and run with limited operators. The 3D printed system can print with different materials, and the interior and exterior walls can be printed simultaneously.

If the customer wants a traditional-looking wall, the BOD2 can attach tools such as grippers for moving bricks or building blocks. By making this technology commercially available, COBOD aims to open possibilities to new construction companies and create options for existing ones.