Just as with automated assembly equipment, process automation requires safety devices that shut down a process in the event of an error to protect workers. These systems typically use a safety controller or safety PLC, which monitors I/O and decides to shut down the dangerous process in the event of an issue.

Emerson is known globally for sensors, such as flow meters, temperature, and pressure sensors, which are often used in process automation applications. Recently, Emerson released the CPS400 safety controller designed to safely control infrastructure, emergency shutdown, fire and gas, and burner management systems.

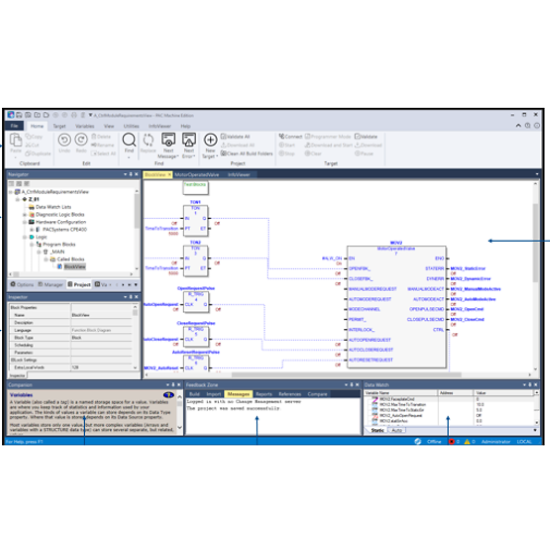

Emerson’s PACSystems RX3i CPS400 safety controller includes built-in, ready-to-use function blocks and templates. Image used courtesy of Emerson

What Is a Safety PLC?

Safety PLCs are very similar to non-safe PLCs. A safety PLC is configured and programmed by integrators and controls engineers. A special development software is used to build safety programs to monitor I/O and ensure the system runs safely. In the event the system becomes unsafe, the safety controller will shut down all sources of energy to protect the operators.

PACSystems RX3i CPS400 Safety Controller

Emerson's new PACSystems RX3i CPS400 is a SIL2-certified safety controller designed for infrastructure, emergency shutdown, and burner management systems. The CPS400 can monitor up to 2,000 I/O points, making the controller a scalable option for complex systems. The CPS400 uses a TPM secure boot platform to ensure top-of-the-line security for its end users and features a 1.2 GHz AMD G series Quad Core processor with 64 mb of memory capacity.

Emerson has designed communication with the safety controller to be simple. It uses supported industrial protocols, such as OPC UA, Ethernet Global Data, and Modbus TCP — all of which are protocols often used within the process automation industry. Additionally, the front of the CPS400 features two USB ports and five Ethernet ports that can support three different networks.

A screenshot of the PAC Machine Edition software. Image used courtesy of Emerson

Programming and Development

Just like any other automation controller, programs need to be developed for the controller to run in order to monitor the correct I/O and to configure shutdown procedures. Emerson also has a line of PLCs designed for process automation applications, and to make programming the CPS400 as convenient as possible, the same PAC Machine Edition development environment can be used for configuration and programming the new safety controller.

Emerson’s Machine Edition software uses visual programming languages such as ladder logic and function block diagrams to develop and integrate control programs. This visual approach allows for faster commissioning and integration of the safety system.

A series of pipes, pumps, and tanks that are commonly used in process automation. Image courtesy of Unsplash

Process Automation Safety

Large-scale burners are used to heat solutions for specific processes, but these burners can be quite dangerous, especially if the burner doesn’t light. Some burners use natural gas as a fuel source. The flammable gas enters a combustion chamber and is ignited by an ignition device.

In the event the gas does not ignite, the system needs to shut down the gas supply. Flame sensors can be used to detect when a flame is or is not present, and a safety controller is used to monitor the flame sensor and shut down the gas supply if the flame doesn’t ignite.

These types of mass production of chemicals and energy require process automation tools such as the CPS400 safety controller. These controllers execute programs within milliseconds and shut down processes before operators get hurt.