Yaskawa has introduced the iQpump605, the latest evolution in its intelligent pump drive lineup. Designed to make pumping systems more efficient, reliable, and easier to manage, the drive features guided setup, mobile monitoring, and advanced motor protection. Covering applications from small irrigation pumps to large municipal systems, the iQpump605 automatically adjusts to demand, reducing energy consumption and wear while maintaining steady flow and consistent performance in any environment.

Pumps are used in various everyday applications ranging from irrigation fields to wastewater management systems. Image used courtesy of Adobe Stock

The iQpump605 is Yaskawa’s next step in intelligent pump control. The new drive expands on the iQpump1000 platform by improving usability, flexibility, and connectivity. A step-by-step setup wizard guides users through configuration using plain pump terminology, and built-in application presets shorten commissioning time. Real-time monitoring, onboard data logging, and Bluetooth connectivity through the DriveWizard Mobile app help operators track and tune performance directly from a smartphone or tablet.

Ready for Whatever You Throw At It

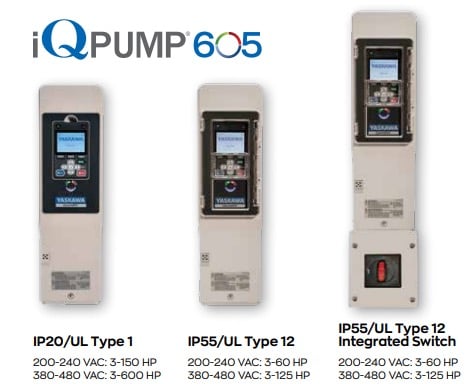

Yaskawa offers the iQpump605 in several enclosure configurations, including IP20, IP55, and UL Type 3R, covering indoor and outdoor use. Depending on the setup, the drive lineup runs anywhere from 3 to 600 horsepower, making it just as useful for a small irrigation pump as it is for a full city water system. The IP55 outdoor versions have been purchased with an integrated disconnect switch for faster maintenance and safety compliance.

The iQpump605 drive lineup offers multiple enclosure options, from compact IP20 units to outdoor-rated UL Type 3R models, to suit nearly any installation. Image used courtesy of Yaskawa

The drive is designed for long service life, using conformal-coated circuit boards to guard against moisture and dust. Built-in line impedance helps limit harmonic distortion and electrical stress on connected equipment. Together, these measures improve reliability and reduce the need for scheduled maintenance over a typical 10-year operating span.

Runs Lean, Plays Well with Others

Energy use remains the biggest cost driver in pumping systems, so the iQpump605 continuously adjusts motor speed to match system demand. This keeps the pump operating near its best efficiency point, reducing both power draw and wear. Integrated motor protection and flow monitoring also help prevent cavitation, dry running, or overload conditions before they escalate into costly downtime.

The iQpump605 is available in IP20, IP55, and UL Type 3R configurations. Image used courtesy of Yaskawa

From a control standpoint, the drive supports all major industrial communication protocols, including EtherNet/IP, Modbus TCP/IP, BACnet, Profibus, and LonWorks. This makes integration into existing PLC and SCADA networks straightforward, with native support for multiplex control in multi-pump systems.

A Family of Pump Drives

The iQpump605 joins the iQpump family of Yaskawa pump drives built for different installation scales and operating conditions. The iQpump1000 was designed for municipal and large commercial systems, offering broad horsepower coverage and comprehensive motor protection. The iQpump Micro carries that same control logic into smaller, cost-sensitive setups such as agricultural or building systems.

For sites requiring strict power quality, the U1000 iQpump uses matrix-converter technology to maintain low harmonic distortion under 5%, meeting IEEE 519 standards. Enclosed Configured and Enclosed Bypass packages extend these drives for indoor and outdoor use, giving operators pre-engineered solutions that simplify installation and minimize downtime.

The iQpump605 can quietly handle the constant adjustments, keeping everything balanced without much fuss. It's built-in logic monitors demand, protects the motor, and manages flow to prevent conditions like cavitation or overload before they become a problem. It’s not meant to replace operator control, just to make daily operation smoother, more consistent, and less hands-on for the people keeping the pumps online.