HMS Networks announced its Siemens-certified Anybus Wireless Bolt 5G. The robust and rugged wireless connectivity device is designed to harness the low-latency power of 5G and WiFi 6 connectivity. The Anybus Wireless Bolt 5G features security and cybersecurity features for enhanced safety, built-in antennas for ease of integration, plug-and-play installation, and flexible industrial communication protocol connectivity.

The Anybus Wireless Bolt 5G is compact, cabinet/machine-mountable, and comes with a web-based configuration interface. Image used courtesy of HMS Networks

Connectivity Challenge

Automated industrial settings face several challenges concerning wireless 5G connectivity. Industrial environments can contain a diverse array of hardware and software provided by different companies, which means different installation, setup, and operational protocols. The challenge lies in accommodating a wide variety of devices while optimizing interoperability to reduce downtime and maintain/boost operational efficiencies.

Ultra-low latency (<10 milliseconds) is required in industrial settings for motion control, robotics, and remote oversight of operations. The infrastructure integrity, the public or private nature of the network, and the device's hardware and software capabilities may affect how well 5G technology performs. Common issues like network jitter, inadequate antenna design, and outdated firmware can obstruct and delay mission-critical automation systems.

Manufacturers frequently use a variety of equipment from many suppliers, such as Siemens, Universal Robots, KUKA, ABB, or Rockwell, and each one uses a unique industrial protocol, such as PROFINET or Modbus. The inability of many 5G-enabled devices to implement these protocols natively or to be certified to integrate effectively with proprietary systems leads developers to rely on laborious compatibility testing or proprietary gateways. When it comes to firmware upgrades, security regulations, or protocol inconsistencies, in particular, this complexity delays installations, raises expenses, and increases risk.

Anybus Wireless Bolt 5G

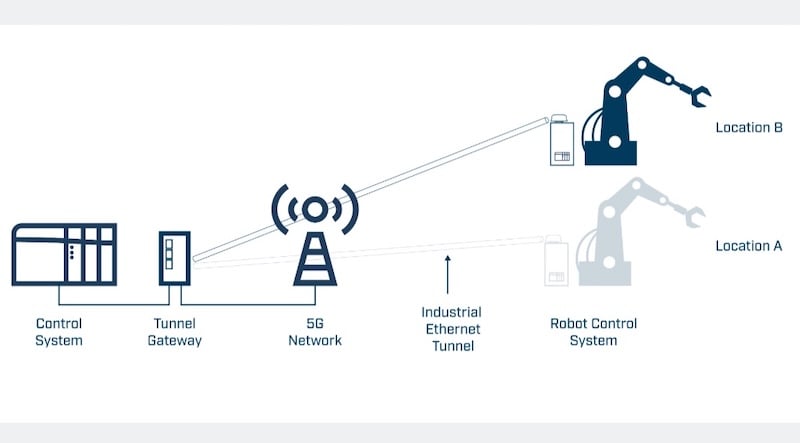

The wireless Anybus system is paired with the Anybus Tunnel Gateway to provide 5G-enabled communication across several key industrial networks (PROFINET, EtherNet/IP, or Modbus TCP, in addition to all TCP and UDP-based communication). The industrial ethernet tunnel serves as a bridge, enabling LLDP and device discovery, connecting low-level communication (layer 2) with the 5G network (layer 3) to the Anybus Wireless Bolt 5G. This makes the Bolt 5G applicable to real-time and deterministic protocols.

The top section of the device uses a rubber gasket seal, achieving an ingress protection rating of IP67. This rating means that the device is impervious to the ingress of dust and other solid particulates and can be submerged (temporarily) in water at a depth of a meter for 30 minutes. The internal safety rating for the device is IP30, protecting tools and wires more than 2.5 mm.

With the Anybus Wireless Bolt 5G and the Anybus Tunnel Gateway, no programming is needed when moving industrial machinery. The PLC or industrial controller will still register machinery as connected through an ethernet cable. Image used courtesy of HMS Networks

Customers can mount the Anybus Wireless Bolt 5G on cabinets or machinery with M50 hole mounting and run it using a single cable with power over ethernet. Users can also power up using the provided 24 VDC power connector.

The Bolt 5G supports 3GPP Release 16 (also called “5G Phase 2”), a new revolutionary 5G technology with ultra-reliable low-latency communications, Time-Sensitive Networking (TSN), and vehicle-to-everything (V2X) communications. TSN provides synchronized timing across devices, big data transmission, low jitter, bounded latency, and predictable/consistent communication.

TSN promotes interoperability by linking operational and information technology (OT/IT) to facilitate a unified network (both wireless ethernet and wired). Network integration with TSN reduces setup and maintenance costs while enhancing connection. For Industry 4.0 and IIoT (Industrial Internet of Things), it facilitates accurate, time-sensitive data flow, improving operational visibility and enabling quicker reactions to shifting demands.

Use Cases

The Bolt 5G is intended for industrial applications where dependable, rapid information transfer is essential, such as linking robotic technologies, programmable logic controllers (PLCs), autonomous guided vehicles (AGVs), and human-machine interfaces (HMIs) in automation systems. It allows machine-to-cloud communication, real-time control, and remote surveillance without changing current network setups. It is suitable for eliminating physical connections in both modern and legacy systems because it can link industrial Ethernet protocols over 5G, allowing for adaptable implementation in industrial IoT contexts and smart factories.

Overall Impact

With its support for 3GPP Release 16, the Siemens-certified Bolt 5G offers low-latency connectivity appropriate for industrial applications. Interoperability testing by Siemens verifies that it is compatible with their systems, allowing integration without requiring any modifications. The device is made to be easily deployed in mixed-vendor systems and supports several industrial Ethernet protocols. This accreditation promotes the wider adoption of 5G in industrial environments and speeds up implementation.