Industrial automation systems can face numerous challenges that range from device connectivity, safety, and system reliability. On top of this, industries must meet increasing safety standards while keeping installation and maintenance costs low, especially in environments that demand both flexibility and ruggedness.

The NET-BOX from IDEM Safety Switches offers a robust and highly configurable solution to tackle these very challenges. The enclosure has been engineered with a choice of a stainless steel or a newly added die-cast metal enclosure and serves as a versatile push button control station and distributed I/O device.

IDEM Safety has added a die-cast metal version to its NET-BOX network-enabled control station offerings. Image used courtesy of IDEM Safety Switches

The NET-BOX Control Station

The NET-BOX network-enabled push button control station is designed to easily integrate with industrial networks via PROFINET PROFIsafe and EtherNetT/IP CIP Safety protocols, ensuring both safety and communication standards are met.

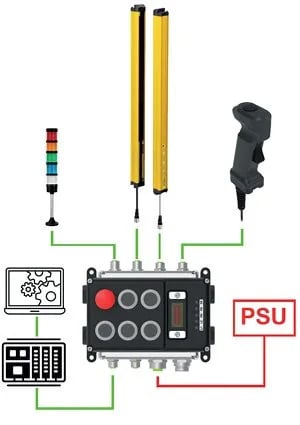

The NET-BOX’s value lies in its ability to simplify complex industrial systems, as the device can support up to four M12 connectors, which integrate various safety devices like sensors, light curtains, and proximity switches into one centralized system and give machine builders the capability to dramatically reduce the need for complex wiring and extensive installation efforts.

The NET-BOX is also able to support up to six pilot devices, such as illuminated push buttons, selector switches, and indicator lamps that can provide operators with clear, accessible control interfaces that improve safety, workflow, and a simpler troubleshooting method.

The NET-BOX can support up to six pilot devices ranging from stack lights to safety light curtains. Image used courtesy of IDEM Safety Switches

Die-Cast Metal Enclosure

The NET-BOX enclosure is available in two versions: a newly added rugged die-cast metal enclosure that has been designed for heavy-duty environments and a stainless steel, mirror-polished option that is ideal for washdown applications where corrosion resistance is crucial. The NET-BOX stainless-steel enclosure option can also be equipped with silicone push-button covers that meet IP69K standards, ensuring resistance to high-pressure cleaning, which is ideal for the food and beverage industries or chemical manufacturing plants. Both enclosure's top connector plates can be configured with different combinations of M12 5-pin and 8-pin connectors.

The NET-BOX can be purchased as a mirror-polished 316 stainless steel variant for washdown applications. Image used courtesy of IDEM Safety Switches

Network-Enabled Control

Safety will always be a concern in industrial settings, and the NET-BOX has been designed with rigorous standards in mind. The NET-BOX has been independently tested and certified by TÜV and cULus to meet the highest safety classifications, including CAT4, SIL3, and PLe. The system’s built-in dual-channel safety inputs and outputs further enhance its ability to manage actuator control and monitor safety devices in real time.

The NET-BOX also incorporates an integrated network switch that can simplify the connectivity process by allowing devices to be daisy-chained together while reducing wiring complexity. With a web interface that provides easy access to real-time data and centralized monitoring, the NET-BOX gives operators enhanced control and visibility over their automation systems.