Virtually every machine needs a way for an operator to interact with automated equipment. These interactions might be as simple as clearing alarms or as advanced as adjusting parameters. The human-machine interface (HMI) is the device that facilitates this interaction, and there are many different options available on the market. Recently, Mitsubishi Electric has added another version to the industry, the GOT3000 series of HMIs.

Mitsubishi’s GOT3000 widescreen models feature a high-definition PCAP touch screen. Image used courtesy of Mitsubishi Electric

The GOT3000 Series HMI

Mitsubishi’s latest graphic operation terminal (GOT), the GOT3000 series, offers new features and a fast, responsive interface to help Mitsubishi stay competitive in the IIoT market. Features such as a standard OPC UA server and VPN capabilities allow the terminal to gather data from automation devices and deliver it to higher-level components. The VPN connection facilitates a secure remote connection to the HMI for troubleshooting or simple operation via an internet connection.

The GOT3000 comes in eight versions with screen sizes ranging from 8.4 inches to 15.6 inches. The wide 12.1-inch and 15.6-inch modules use a PCAP responsive touch screen display and feature a high-definition display. Dual Ethernet ports are provided for maximum connection possibilities, and a front-facing USB-C port offers easy file transfer or adapter connections. An installed web browser allows technicians to connect and configure connected devices that have a web interface.

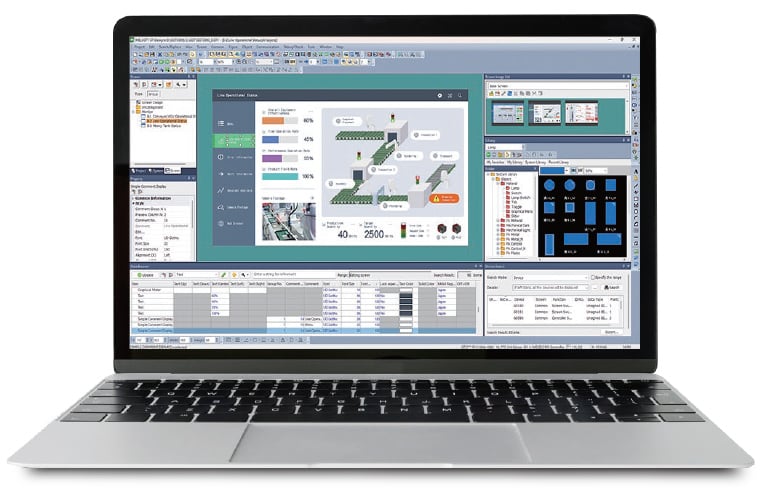

The GOT3000 series can be configured with Mitsubishi’s Melsoft GT Works3 HMI development software. Image used courtesy of Mitsubishi Electric

HMI Software

Every HMI needs software to develop the interaction application, and the GOT3000 uses Mitsubishi’s Melsoft GT Works3. This screen design software uses images for each screen, making searching for a particular screen easier. A library is included as well for selecting professional-looking images and inserting animations. The software's layout is designed to be intuitive and similar to other development software.

Simulating Applications

Debugging an HMI application is an important step in the development process. The Melsoft GT software interacts with the GT simulator3 software that emulates a user’s controller. By simulating both the controller and HMI, developers can debug applications before the equipment arrives and shorten the integration time.

The GOT3000 series is available in eight models, with screen sizes ranging from 8.4 inches to 15.6 inches. Image used courtesy of Mitsubishi Electric

HMI’s Advancing Technology

The HMI used to be a very simple computer that ran the runtime software and could only connect to the PLC of the same brand. Today, we have HMIs like the GOT3000 that not only connect to any PLC brand but also send data to the IT level infrastructure. This topology reduces the number of components needed and the number of times data is passed from one device to another. Machine builders can now use the HMI to collect data from the PLC or automation device and pass it directly to the IT data collection system.

These advanced HMIs also feature enhanced graphics and better touch screen interfaces. Many HMIs today feature high-resolution and vibrant colour screens to display indicators and images without eye fatigue.

Mitsubishi's GOT3000 series highlights the constant development of HMIs that enable machine builders and technicians to build faster, brighter, and smarter HMI applications.