Industrial automation is full of moving parts, but traditional connectors can’t always keep pace. Phoenix Contact’s NearFi technology eliminates physical wear points by transmitting both power and Ethernet data across short air gaps—no mechanical contact required. Designed for robotics, AGVs, and other high-mobility systems, NearFi supports all major protocols without configuration. This flexible, wear-resistant solution helps reduce downtime, cut maintenance costs, and extend the service life of moving equipment in demanding environments.

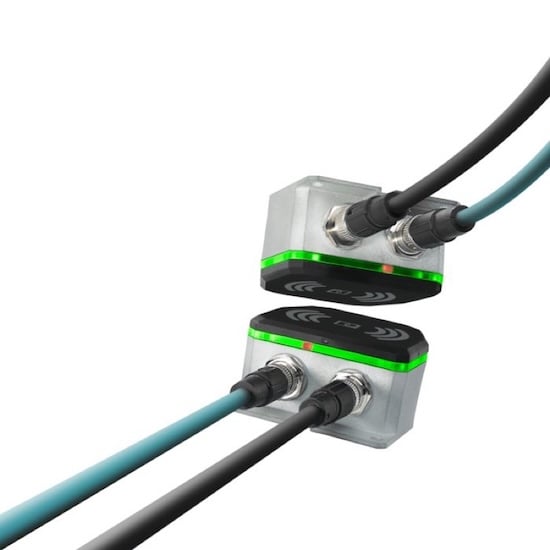

NearFi eliminates physical wear points by transmitting power and data across air gaps in moving industrial systems. Image used courtesy of Phoenix Contact

Real-time Ethernet and Contactless Power in One Compact System

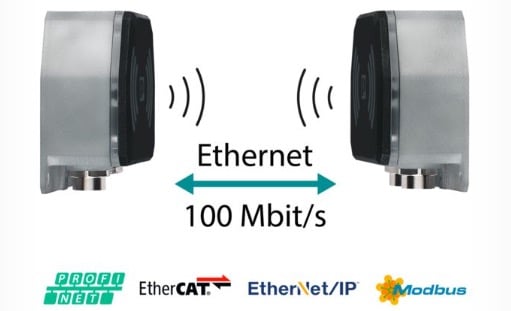

NearFi provides Ethernet and power transmission across short air gaps without physical contact. The NearFi contact supports 100 Mbps full-duplex Ethernet and works with widely used industrial protocols such as EtherNet/IP, PROFINET, Modbus, EtherCAT, and TSN. The NearFi system is protocol-transparent and requires no configuration, making it ideal for time-sensitive applications that rely on quick startup. NearFi operates across air gaps of up to 40 millimeters when transmitting only data. For applications requiring power, or both power and data, the system supports distances up to 12 millimeters, meeting the needs of rotating, sliding, or mobile systems where alignment flexibility is essential.

NearFi transmits 100 Mbps Ethernet and power across short air gaps, supporting all major protocols with no configuration required. Image used courtesy of Pheonix Contact

Power is transmitted inductively, with a single NearFi pair capable of delivering 50 watts. Using two pairs in parallel increases the total power to 100 watts with automatic current balancing. Depending on the application, the system can also supply two electrically isolated 50-watt power rails. Because there are no exposed contacts, NearFi is highly resistant to dust, vibration, and mechanical wear. The couplers are housed in IP65-rated enclosures and use standard M12 connectors for Ethernet and power, making installation straightforward and reliable even in harsh industrial environments.

Flexible mounting and simple setup

The NearFi couplers do not require precise alignment. They can be installed facing each other directly, at an angle, or even with some lateral offset. The system is also tolerant of rotation, which opens up many possibilities in applications with moving equipment. This flexibility reduces mechanical design constraints and makes integration easier.

The system consists of a base unit and a remote coupler. No programming or configuration is needed. Once powered, the couplers begin communicating automatically. Bright LED indicators around the housing provide 360-degree visibility for alignment and diagnostics, helping technicians verify operation at a glance.

Built for automation on the move

NearFi is particularly effective in automation environments where components move constantly. Robots that perform frequent tool changes, rotary indexing tables, and AGVs all benefit from its contactless design. These are the applications where cables wear out, slip rings need frequent replacement, or connectors become unreliable over time.

In a robotic setup, NearFi makes it possible to send power and data to a rotating tool head without the hassle of physical connectors. This eliminates common failure points and simplifies maintenance. For automated guided vehicles, NearFi provides a reliable way to exchange data with docking stations or production equipment without the wear and tear that usually comes with traditional wired connections.

The NearFi coupler can be used for automatic tool changes in robotic applications. Image used courtesy of Pheonix Contact

NearFi allows industrial designers to eliminate failure-prone connections without changing protocols or sacrificing performance. With contactless power and Ethernet over short distances, it simplifies system architecture, reduces maintenance costs, and extends the service life of moving machinery.