Industrial plants depend on accurate, real-time visibility into storage tanks. Yet, many facilities still rely on manual readings or legacy systems stitched together from separate displays, communication modules, and data concentrators. This fragmented setup adds cost, slows decision-making, and makes automation difficult to scale. Emerson’s new Rosemount 2405 Monitoring Hub addresses the problem from a different angle by collapsing that complexity into a single, unified device that gathers, calculates, visualizes, and distributes tank inventory data with far less effort.

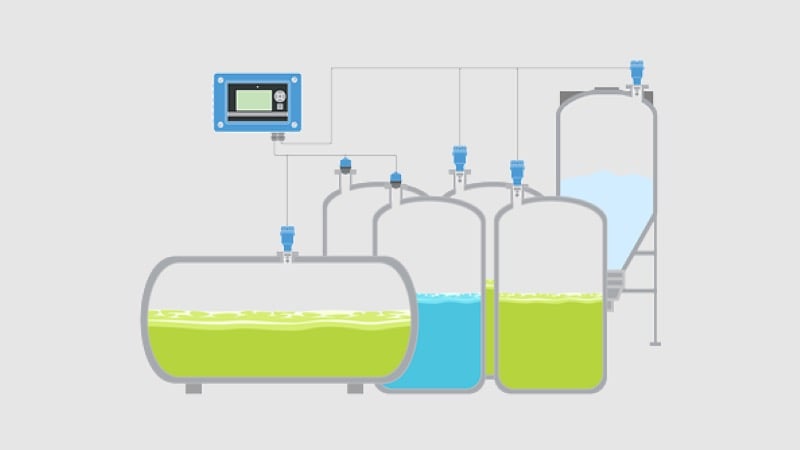

The Rosemount 2405 combines the roles of display, data concentrator, and communication gateway. Instead of forcing the user to install and integrate multiple pieces of hardware, the hub serves as a complete inventory point for up to eight tanks. It collects level, temperature, and pressure data from HART-enabled field transmitters. It then consolidates that data into a clear picture of tank status, accessible both locally via a color field display and remotely via a built-in web server. For operations that have struggled to justify the cost and complexity of automated monitoring, this all-in-one architecture significantly lowers the barrier to adoption.

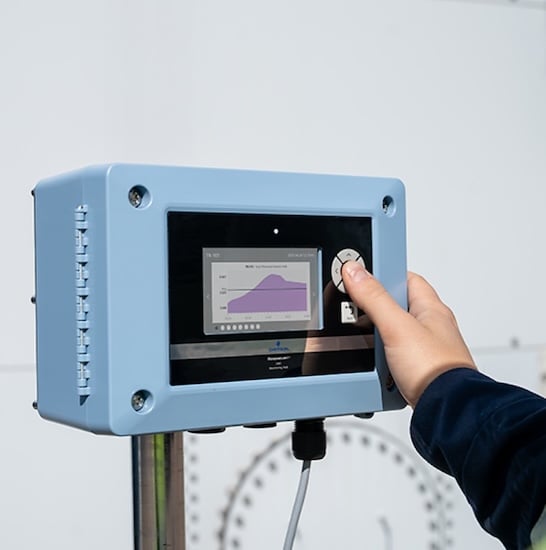

The Rosemount 2405 Monitoring Hub provides local access to live tank and inventory data through its integrated field display. Image used courtesy of Emerson

A Single Hub for Multi-Tank Insight

What sets the Rosemount 2405 apart is its ability to function as the centerpiece of a simplified monitoring architecture. Because it supports HART multidrop communication, multiple instruments can share a single twisted-pair cable. That alone reduces wiring requirements, minimizes the number of junction boxes and input channels, and removes many of the installation bottlenecks that historically made tank automation expensive.

The hub does more than relay raw measurement values. It performs the calculations needed for inventory reporting, including volume, utilization, rates, and other metrics that operators use to plan production, schedule deliveries, and forecast consumption. By consolidating data from several tanks into a single device, it eliminates the patchwork of interfaces that often complicates inventory management and creates gaps in situational awareness. Plants that previously depended on clipboards or occasional manual readings can move toward continuous, real-time oversight with a relatively modest system upgrade.

The Rosemount 2405 serves as a central data concentrator for multiple HART-enabled instruments, simplifying wiring and consolidating tank measurements. Image used courtesy of Emerson

Real-Time Data with Flexible Access

The 2405 fits a broader shift in industrial plants: operators expect to see key information wherever they’re working. The 2405’s built-in graphical display lets field personnel check levels, review trends, and confirm alarms without returning to the control room. At the same time, the built-in web server provides browser-based access, ensuring that the same dataset is available remotely over Ethernet using Modbus TCP/IP or HART-IP.

This dual-access approach supports Emerson’s broader push toward data mobility. In many plants, decision-making stalls because information is trapped in isolated systems or available only at specific workstations. By pushing tank data to both local displays and digital platforms such as Rosemount TankMaster and TankMaster Mobile, the 2405 creates a consistent, accessible source of truth for inventory tracking.

Another benefit of digital HART connectivity is the transmission of diagnostics alongside process variables. Rather than discovering problems only after a device has slipped out of calibration or stopped working, technicians can spot irregular behavior early. That visibility helps prevent unplanned downtime and keeps operations running safely and consistently.

Simplified Configuration and Operation

Beyond instrumentation, configuration challenges often slow tank monitoring systems. Each transmitter must be correctly set up, connected to the concentrator, integrated with the host, and verified at startup. The Rosemount 2405 addresses this through an intuitive interface and guided configuration sequences that walk users through each step, reducing both setup time and training requirements.

Troubleshooting follows a similar approach. Clear status indicators and accessible diagnostics help operators quickly isolate issues, from communication interruptions to unexpected readings. When a facility manages dozens or hundreds of tanks, this kind of simplified problem-solving can significantly reduce operational drag.

Applications Across Process Industries

The impact of the 2405 is clearest in industries where accurate tank inventory is essential. In chemical storage, relying on manual readings can yield inconsistent data and make it harder to plan stock effectively. Bringing those measurements into an automated, real-time system improves scheduling and helps prevent both overfilling and unexpected shortages. The hub can pair with devices like the Rosemount 1208 level transmitter and 248 temperature transmitter to monitor chlorine vessels in water and wastewater operations. Maintaining stable levels and temperatures ensures proper dosing and supports consistent water quality. Similar benefits are seen in refining, mining, food and beverage, and other sectors where tank-based materials must be continuously measured and tracked.

Engineering for Practical Deployment

The Monitoring Hub’s hardware reflects the realities of industrial environments. It supports a full range of power supplies, withstands temperatures from -40 to 60° C, and carries IP66/67 and Type 4X enclosure ratings for harsh conditions. Multiple analog and relay outputs, along with Ethernet connectivity, give it the flexibility to integrate with both modern and legacy systems. These features reflect a design built around practicality, cutting down the amount of hardware needed, making installation straightforward, and keeping information easy to interpret while still working smoothly with the instruments plants already rely on. For teams used to managing a tangle of separate displays, concentrators, and communication units, the 2405 marks a real move toward a cleaner, more unified way of working.

Toward More Accessible Automation

While many facilities have long recognized the benefits of automated tank monitoring, the cost and complexity of implementation have held them back. The Rosemount 2405 Monitoring Hub lowers that threshold. It provides a path to modern inventory management without forcing a complete system overhaul by merging multiple functions into one device and enabling straightforward connectivity to both Emerson and third-party platforms.

For sites looking to improve accuracy, speed up decision-making, and run more efficiently, the 2405 isn’t a replacement for everything they already have; it’s a way to get more out of what they already have. By giving operators a clearer view of their tank inventory and removing much of the hassle that usually comes with new systems, the hub becomes a simple, practical step forward for facilities wanting to leave manual readings and scattered tools behind.