Part of ABB’s latest investment of $110 million will be channeled into constructing a production line in Mississippi, which will focus on manufacturing ABB’s SACE Emax 3 circuit breakers. ABB is also targeting expansion of its Pintetops, Selmer, and Richmond facilities to increase the production of electrification solutions and technologies. The investment forms part of a strategy to support energy infrastructure growth.

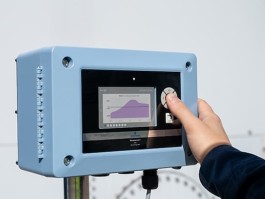

Users can upgrade Emax 3 using Ekip Aware to accommodate changing protection, communication, and measurement requirements. Image used courtesy of ABB

More Data Demands More Power

According to the IEA’s Electricity Mid-Year Update 2025, wholesale electricity prices jumped by about 30-40% in the first half of the year. Large buyers such as utilities, data centers, power generators, and large industrial customers would typically pay these wholesale prices. Advancing in parallel is the advancement of artificial intelligence, growth in associated technologies, and consequent growth in data and data inventories, which is concentrating electricity demand (needed by data centers and cryptocurrency mines) and price increases—especially for PJM states.

ABB’s Emax 3 Circuit Breakers

ABB’s investment is intended to help establish a $15 million production line in Senatobia, Mississippi. The production line will roll out ABB’s innovative Emax 3 air circuit breakers. The Emax 3 circuit breakers feature a system and equipment-agnostic design for easy integration within existing infrastructures.

The Emax 3 circuit breaker range includes highly advanced sensors providing measurements with an accuracy of 0.5 % for Active Power and Energy. The device tracks voltage, current, and harmonics by using advanced data loggers (with SD card) and network analyzers. Twelve sensors per circuit breaker offer rapid arc-flash detection and protection, and added safety is provided by incorporating enhanced mechanical interlocks, keylocks, and padlocks. In data center electrical systems, keylocks and padlocks preserve uptime by preventing unintended breaker operation during repair. Mechanical interlocks ensure backup generators and grid power do not connect simultaneously, preventing major failures.

Emax 3 provides users with an intuitive human-machine interface with a simple menu, mobile-accessible EPiC app, and Ekip Connect software tool for monitoring, commissioning, diagnosing, testing, and setting up low-voltage devices. Users can access historical electrical values, real-time data, and device health to pinpoint anomalies.

ABB’s Emax 3 circuit breakers are designed to enhance power distribution system security, efficiency, and flexibility. Video used courtesy of ABB

Customers benefit from top-tier cybersecurity through IEC (International Electrotechnical Commission) 62443-4-2 (Security Level 2) cybersecurity standard. This means firmware updates to Emax 3 can only occur via a verified ABB code. Users cannot upload older firmware, which may have security vulnerabilities. The IEC standard also prevents the anti-tampering of device settings and uses security artifacts to secure communications between original modules and ABB tools. ABB account management is role-based (Viewer, Operator, Engineer, Admin, Owner) for added safety.

Real-time data concerning asset status and health ensures optimum predictive maintenance measures, preventing unnecessary breakdowns and system failures. Temperature monitoring helps keep track of breaker performance under load and ambient conditions.

Further Production Line Expansion

ABB is taking significant steps to increase its manufacturing presence in the U.S. It pledged $120 million in March 2025 for plants in Senatobia, Mississippi, and Selmer, Tennessee, with an additional $20 million reserved for Selmer to increase manufacturing capacity. In the meantime, ABB is spending more than $30 million in Arecibo, Puerto Rico, to establish three new production lines for switching components and smart circuit breakers, which will create 90 skilled employment opportunities by 2026.

There is more growth to come. With an enhanced location scheduled to open in 2026, ABB is investing $35 million in its Pinetops, North Carolina, plant to address the growing demand for advanced grid components from utilities, data centers, and industrial enterprises. Another $30 million will go to ABB's Richmond facility in Virginia. This investment will increase the facility's capacity with a new test center, warehouse, and assembly lines for electrification solutions that can help safeguard industrial systems, data centers, and hospital machines and equipment. This plant, scheduled to open in late 2025, will create approximately 100 new production and engineering positions.