The first two days of the ProMat trade show in Chicago have been a huge success, with the many forms of material handling technology stealing the show. Storage racks and shelving stretch to the ceiling, with AMRs and automated forklifts transporting boxes, and even bipedal robots assisting in the tasks of picking and placing crates.

The Control.com team has been busy meeting with exhibitors and learning about the newest technology. We have collected some of the exciting news and demonstrations to share.

Murrelektronik

If the theme of modern automation could be summed up in one word, it might be ‘modular.’ By designing systems in separate, compatible modules, designs can be adapted to ever-changing situations and updates in technology.

Controller, safety, vision, and connectivity equipment from Murrelektronik.

Murrelektronik illustrated this concept with a complete set of devices from controller to vision, and CIP safety I/O. The only interconnectivity required is a simple network cable to facilitate the commissioning. Since the control devices are attached to the modules, each one is rated with sufficient ingress protection (IP) to withstand on-machine distributed installation.

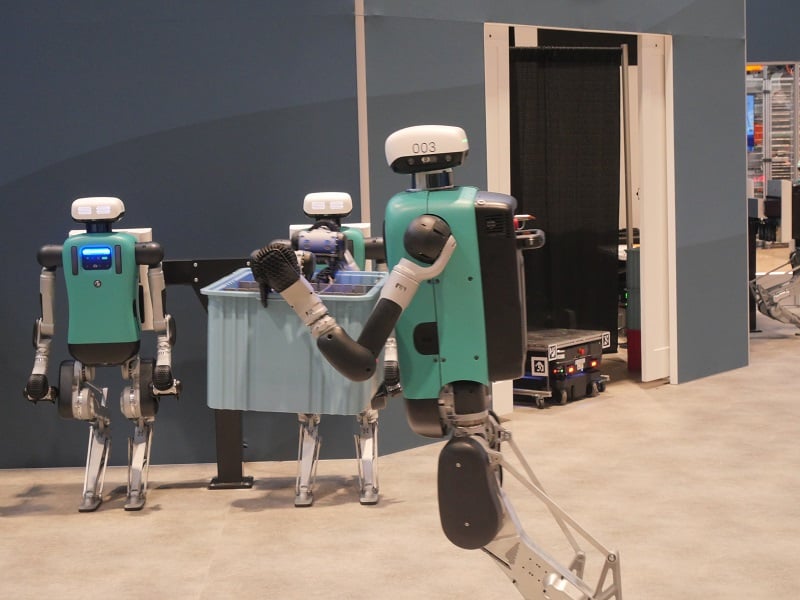

Agility Robotics

Although the concept of ‘humanoid’ robots has existed since the debut of C-3PO in Star Wars, the bipedal form of industrial robotics is still in its infancy. Agility Robotics is on the cutting edge of this innovation.

While one Agility robot moves a crate, several others rest on charging stations behind.

Since the form of a human is well known, the term ‘humanoid robot’ may not always be applicable. These robots may conform to many design adaptations to accomplish various tasks. Therefore, Agility Robotics prefers the term ‘dynamic stability industrial mobile robot’ as a label for these machines, which require power to stay upright. Along with definitions of terms, there is progress being made on safety guidelines for this particular style of robot.

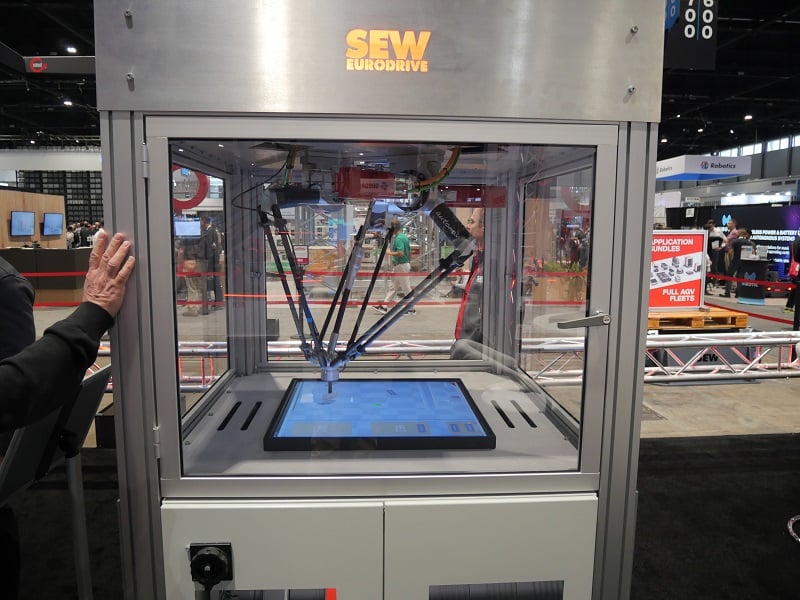

SEW-Eurodrive

Motion control experts have a lot to say about material handling technology. Motors and drives exist inside every robot, AMR, conveyor, and multi-axis gantry in existence.

A delta pick-and-place robot from SEW-Eurodrive.

SEW-Eurodrive incorporated motion into every demonstration, including an AMR, delta robot, synchronized servo motors, and a multi-axis gantry assembly (which also made use of the synchronized motion technology).

Universal Robots

A robot is only as effective as the end tool attached to it. Universal Robots (UR) makes use of the UR+ ecosystem. This consists of hundreds of partner applications, packaging the robot with hardware and software that can easily be integrated into the customer’s specific challenge.

The partnership between MiR mobility and UR manipulation.

Three key UR integrations at the booth were:

- A UR attached to a MiR mobile robot to provide mobile manipulations.

- A modular vacuum gripper with three dynamic fingers from RightHand Robotics.

- A software monitoring application from Olis Robotics.

RightHand Robotics demonstration with unique gripping and bin picking with AI vision.

Schneider

Two new products were on display in the Schneider booth, including distributed I/O and an energy-saving contactor.

The Modicon Edge I/O NTS consists of bus communication modules, power delivery, and hundreds of I/O module variations to provide secure connections between field devices and control systems. The security comes from the use of OPC-UA for the backplane communication, known for its cybersecurity.

The new line of Modicon edge I/O devices.

The TeSys Deca Advanced is a series of contactors that use current monitoring to reduce high energy consumption during initial and sustained energizing. Typically, contactors require more ‘pull-in’ current than the amount required to remain in the contacted position. The Deca Advanced is rated to reduce both current levels, resulting in much higher efficiency.

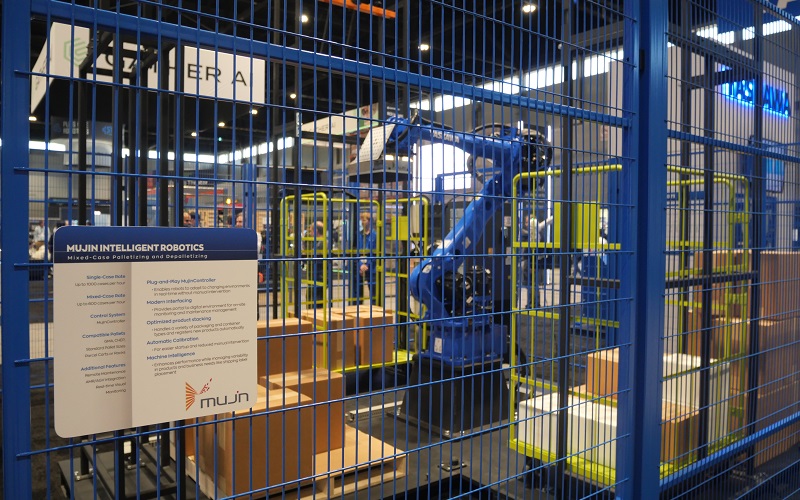

Yaskawa

Loading and unloading pallets is a critical part of the supply chain process. Yaskawa has partnered with Mujin, a company that develops software that can connect directly to the robot controls at a low enough level to compute motion commands and send them directly to the motors.

Yaskawa Robotics paired with Mujin controls.

Using the controllers from Mujin, specialized applications can be made more efficient by using the motion path planning algorithms pioneered by Mujin, making use of many path iterations using AI and high-powered processors.

ProMat 2025

Stay tuned for more updates from the show, and be sure to follow @Control-com on LinkedIn to see videos, pictures, and posts from our editorial and engineering team.