WEG has recently introduced its RUW200 Remote Unit. This compact, modular system has been built for smarter, more connected operations to simplify device integration and optimize efficiency. The RUW200 supports a range of communication protocols that include EtherNet/IP, Modbus-TCP, and MQTT while also offering scalable I/O expansion and seamless interoperability with WEG’s programmable logic controllers (PLCs) and other systems.

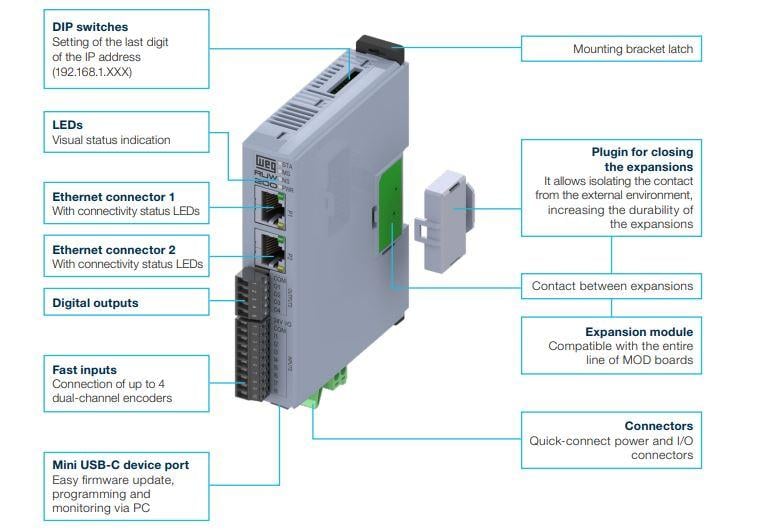

Introducing the RUW200 modular remote unit that has been designed to optimize and decentralize automated systems. Image used courtesy of WEG

Modular, Scalable Architecture for Diverse Needs

The RUW200 is built with a modular book-style format that allows users to add up to eight I/O expansion boards, supporting everything from digital and analog signals to thermocouples, RTDs, and even load cells. Each board is just 25 mm wide, helping save space inside industrial panels.

Expansion is plug-and-play, meaning no specialized wiring or programming tweaks are required when adding new modules. A protective plug-in closure shields contact points from environmental contaminants, helping extend hardware longevity even in harsh industrial settings. Quick connectors for power and I/O simplify cabling and make it easier to scale on the fly without extended downtime.

Communication and Interoperability

With two built-in Ethernet ports, the unit supports EtherNet/IP and Modbus-TCP stock, allowing it to communicate effortlessly with virtually any industrial controller on the market. A simple DIP switch on the unit lets users configure IP addresses directly, speeding up deployment and reducing the chance of errors.

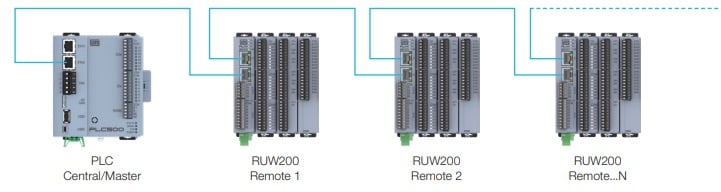

The RUW200 provides multiple benefits, ranging from plug-and-play expansion to scalable remote I/O. Image used courtesy of WEG

WEG customers will also be able to utilize its native compatibility with PLC models like the PLC200, PLC410, and PLC500. The RUW200 also plays nicely with third-party PLCs as well, giving machine builders and system integrators the freedom to design hybrid systems without facing the usual headaches that can be caused when integrating into an existing system.

Ready for Industry 4.0 and Cloud Integration

Automation isn’t just about getting machines to talk to each other, but it’s also about turning operational data into actionable intelligence. That’s why the RUW200 comes “IoT-ready,” by featuring built-in support for the MQTT protocol. This allows the unit to connect directly to cloud platforms such as WEGnology, WEG’s proprietary monitoring and analytics suite.

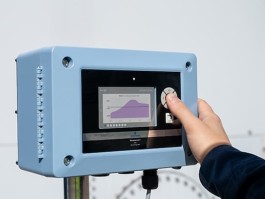

These remote units can be daisy-chained and distributed throughout your automated process to connect your sensors to a centralized controller. Image used courtesy of WEG

Once connected, users can visualize machine performance, generate custom dashboards, monitor KPIs, and set up real-time alerts using email or SMS. The system also supports predictive maintenance strategies that enable operators to address issues before they result in unnecessary and costly downtime. The RUW200 also integrates with ERP and MES systems, helping manufacturers streamline both their operations and business processes.

Simplified Programming with WPS

Programming with the RUW200 is pretty user-friendly as compared to other brands. WEG’s WPS (WEG Programming Suite) allows engineers to configure the unit via USB or Ethernet and develop localized logic using SoftPLC, all while complying with the IEC 61131-3 standard. Support for both ladder diagram (LD) and structured text (ST) languages ensures flexibility for different user preferences. Whether updating parameters or building a new automation logic tree, WPS cuts down on programming time and complexity.