Wiring a control panel is often a bottleneck, being slow, tedious, and monotonous work. For high-volume operations, delays in assembling cabinets can easily drive up costs. When you add a maze of cables and connections, it’s clear why system integrators need a faster, more reliable alternative.

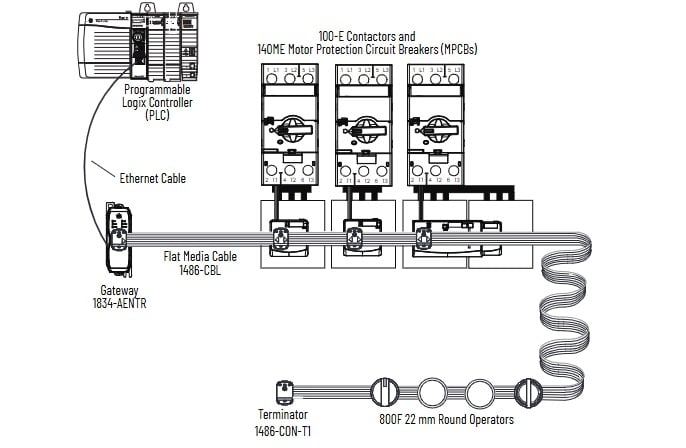

The in-cabinet Ethernet IP system can simplify wiring and prevent common human errors when compared to traditionally wired systems. Image used courtesy of Rockwell Automation

Rockwell Automation has recently released a pretty unique product that could make this monotonous work a thing of the past, at least for some systems. With their in-cabinet Ethernet I/P system, traditional panel wiring that involves complex bundles of cables may now be simplified using a network connection. Instead of hardwiring each component individually, engineers now connect everything through a single-pair Ethernet cable, cutting wiring time by as much as 80% and delivering a more compact, intelligent, and sustainable control system.

More Than Just Cables, It’s a Smarter Network

So, what exactly makes this system different from a traditionally wired cabinet? Traditional control panels will probably have a multitude of wires to link devices like motor starters, sensors, switches, terminal strips, circuit breakers, fuses, and the list goes on. In a traditional cabinet, each connection must be manually installed and tested, which causes the process to be labor-intensive and leaves room for human error, like miswiring, inconsistent labeling, or even missing connections entirely. Do you always remember to do your pull test?

The in-cabinet solution consists of a gateway, flat media cable, and communication interceptors. Image used courtesy of Rockwell Automation

With Rockwell’s In-Cabinet solution, a 7-conductor flat media cable connects components via Ethernet/IP protocol, which means all devices share the same network for both power and communication, creating a backbone that’s easy to scale and maintain. The single-pair Ethernet cable reduces material costs, space requirements, and the environmental impact of excessive copper and plastic use.

Smarter Wiring, Faster Delivery

Volga, a Brazilian manufacturer specializing in automation and electrical systems, tested the new system and saw wiring times plummet from over twenty hours with traditional methods to just under seven hours using Rockwell’s solution. That’s a 66% time savings in real-world conditions. “The feedback from our team was very positive,” said Carlos Leopoldo, Volga’s Commercial Director. “The technology was easy to use, didn’t require a lot of materials, and the connections were very strong.”

Sustainability Meets Scalability

While faster wiring and easier troubleshooting are obvious wins, the environmental benefits are just as compelling. Smaller panels, which Volga reports a 36% reduction in size and a 32% reduction in weight, mean that fewer materials are consumed in manufacturing and shipping. Less copper and plastic are used, and because the system is more modular and easily upgradeable, it can even adapt over time without requiring a complete redesign.

There needs to be a more efficient way to do things, and by switching to a single-cable solution, it's entirely possible to not only reduce installation times but also lay the groundwork for smarter and more responsive manufacturing environments. Picture being able to diagnose a malfunction from a centralized dashboard in real time or reconfiguring a system digitally without needing to open the panel. That’s the future this solution enables, where the panel isn’t just hardware, but a networked, intelligent hub. Rockwell’s EtherNet/IP In-cabinet Solution offers faster assembly, greater efficiency, and a cleaner, more sustainable design.