Industrial automation doesn’t always happen on pristine factory floors with perfect panel layouts. Sometimes it’s a freezer, a cleanroom, or a piece of equipment crammed into a corner of a lab bench. In those environments, integrated motors don’t always cut it, and traditional motion systems can eat up space, overheat, or simply fail to keep up.

Recently, JVL has introduced three offerings designed to meet the demands of rugged, space-constrained, and performance-critical motion control applications, including the SMC66 stepper motor controller, a modular closed-loop motion control system built around the MSP motor and PA0260 encoder, and the all-new MAC404 integrated servo motor. These systems are designed to address real-world constraints without sacrificing precision or reliability.

The SMC66 controller is designed to deliver high-resolution, closed-loop stepper motor control in a compact and rugged form. Image used courtesy of JVL

SMC66 Stepper Motor Controller

The SMC66 is a compact IP42-rated controller that supports standalone or networked operation with stepper motors ranging from NEMA 08 to NEMA 34. Its flexible I/O options, ultra-high step resolution up to 409,600 steps per revolution, and encoder compatibility enable closed-loop operation in harsh environments and elevated temperatures. Engineers can make real-time adjustments to speed, torque, and other parameters while leveraging encoder inputs for semi or full closed-loop performance.

Built-in ePLC logic allows for custom motion sequences without a PLC, and support for IO-Link, Profinet, EtherCAT, and Modbus TCP/UDP makes integration with industrial controllers straightforward. The controller supports daisy-chaining for multi-axis applications via dual M12 connectors across CANopen or Ethernet networks. Safety is addressed through support for Safe Torque Off (STO) and SIL3 certification, and optional wireless communication enables additional deployment flexibility in difficult-to-wire installations.

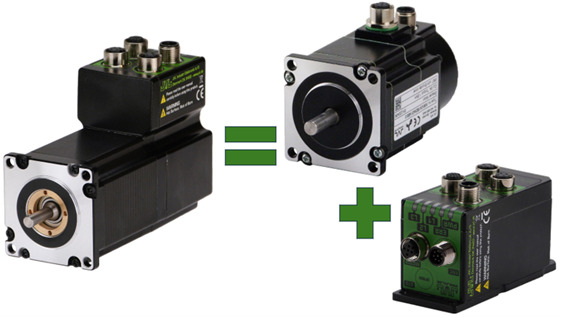

JVL has combined its MSP stepper motor, PA0260 magnetic encoder, and SMC66 motor controller to deliver precise, closed-loop motion control in extreme industrial environments. Image used courtesy of JVL

Modular Closed-Loop Motion Control

When system layout, heat exposure, or harsh conditions make integrated motors impractical, JVL’s modular motion system offers a reliable and scalable alternative. At the core of this solution is the MSP stepper motor, which is available in NEMA 17 through 43 frame sizes and provides holding torque up to 25 Nm. The motor features robust IP65/IP67 options and M12 connectors for secure cabling in industrial settings.

Paired with the PA0260 magnetic encoder and SMC66 stepper motor controller, this setup delivers closed-loop feedback with high precision and environmental resilience. The encoder features magnetic sensing with up to 16-bit resolution, absolute multiturn capability, and a wide temperature operating range from -40 °C to 105 °C. Its resistance to oil, dust, and vibration makes it well-suited for demanding applications like robotics, medical automation, and harsh industrial installations. By separating the controller and motor, this architecture supports better thermal management and easier servicing, while retaining the responsiveness and precision of an integrated system.

The MAC404 servo motor packs 400 W of continuous power and features a built-in drive and controller. Image used courtesy of JVL

MAC404 Integrated Servo Motor

JVL’s MAC404 is a 400 W integrated servo motor that delivers continuous power in a small footprint. Peak power reaches 1.2 kW, and the motor is rated for 100 percent duty cycle, making it ideal for continuous operation in applications such as high-speed packaging, automated warehousing, and lean manufacturing cells. A high-speed processor enables responsive control while minimizing latency in dynamic workloads.

The motor includes an absolute multiturn encoder that operates without batteries and maintains position information across power cycles. By directly embedding the drive and controller into the motor body, the MAC404 can eliminate the need for large external cabinets and significantly reduce setup time. Supported protocols include EtherNet/IP, Profinet, EtherCAT, and more, ensuring compatibility with Siemens, Rockwell, and other major PLC platforms. Daisy-chain capability further simplifies wiring in multi-axis systems.

Enhancing Motion Control

JVL’s new motion control systems and motors reflect a shift toward compact automation that is ready for extreme conditions and tight mechanical constraints. The SMC66 provides versatile stepper control, the MSP, PA0260, and SMC66 motion control solution offers modular closed-loop flexibility, and the MAC404 delivers integrated servo performance in a compact package. JVL has designed its new solutions to give users the freedom to design smarter, more adaptable machines that can perform reliably wherever motion is needed most.