Motion systems such as servo motors require a feedback device to close the control loop. An encoder is used to detect the number of revolutions that the motor’s output has turned. Most encoders today use an optical sensor that detects blank spaces on a coded disk, which creates a pulsed signal that is then translated into shaft position and shaft speed. SICK, a manufacturer of different automation components, has released an absolute encoder with integrated PROFINET communication.

The ANS/ANM58 encoder mounted on a motor shaft. Image used courtesy of SICK

ANS/ANM58 PROFINET Absolute Encoder

The new ANS/ANM58 from SICK is a 58 mm absolute encoder that can be configured for radial or axial type installation, and the encoder can be ordered with a solid, blind hollow, or through hollow shaft configuration. The ANS/ANM58 can be set up with either a single-turn or multiturn measurement system and resolutions of 18-bit or 34-bit. This high resolution offers accurate positioning and reliable speed reporting. This high resolution is made possible by SICK's Opto-ASIC technology.

Synchronizing motions are often used in packaging equipment and welding applications. Thanks to SICK’s Isochronous Real Time (IRT) function, multiple motors with ANS/ANM58 encoders can be easily synchronized. The IRT function uses time stamps that are sent along with the encoder position over the fieldbus network. Positions from multiple motors can then be compared with the help of the time stamp, and their positions can be synchronized.

The ANS/ANM58 encoder features different variants to suit a wide range of motion control applications. Image used courtesy of SICK

Positioning Over Ethernet

PROFINET is a popular fieldbus topology built on the industry standard Ethernet infrastructure. The PROFINET topology is used with the Siemens control system, and the encoder can be configured using the Siemens TIA portal. By having the encoder integrated with PROFINET, additional devices are not required, saving wiring time and money. The ANS/ANM58 can also be configured using the internal web-based configuration software.

The ANS/ANM58 encoder features a compact variant for installation in tight spaces. Image used courtesy of SICK

Precise Motion Control

Many applications use servo motors for speed and precise movements, but if the application requires more accuracy than the standard encoder can provide, an external encoder may be required. Seam tracking in welding applications will often use vision or laser profilers to track where the weld needs to be applied. A servo-driven laser welding device is then used to lay the weld in the guided position. The offset provided by these devices can be very small measurements, so a very precise encoder would have to be used to command a servo to the correct position.

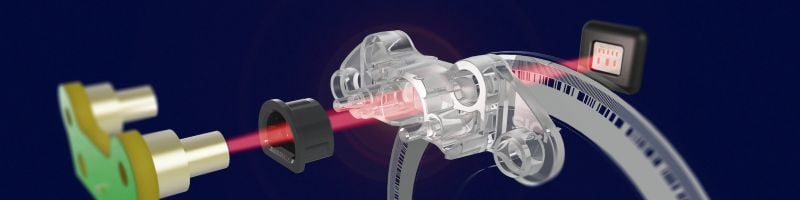

A graphical representation of how the ANS/ANM58 encoder works to detect a motor's position. Image used courtesy of SICK

Choose the Right Encoder for the Job

Just like any device in your automated application, you need to size the encoder for the application you intend to use it for. An encoder that doesn’t have enough resolution won’t be able to detect small enough changes in position. So, next time you are looking for a high-resolution encoder for your application, consider trying SICK’s new ANS/ANM58 PROFINET absolute encoder.