SMC has expanded its EX600 portfolio with a CIP Safety Communication I/O module, bridging pneumatics and field I/O for safer, more efficient machine design. Traditionally, safety I/O required cabinet-mounted relays and complex wiring. With the new EX600 system, safety inputs and outputs can be deployed directly in the field, alongside valve banks and actuators. This reduces panel complexity, cabling, and troubleshooting, while providing machine builders with a streamlined approach to safety integration in modern automation systems.

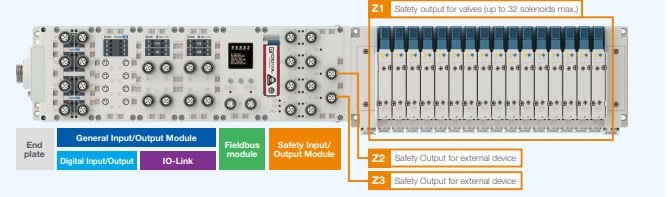

The EX600 contains an IOLink module. Image used courtesy of SMC

I/O In The Field

There are many different ways to implement I/O within an automated system. A popular method for large equipment and factory automation is to use I/O devices in the field. This reduces cable runs and wiring time and eliminates the need for large PLC racks filled with input and output cards. Regarding safety, machine builders will often still use safety input and output cards because of the lack of CIP safety field I/O devices. Recently, SMC released a safety communication fieldbus system for its EX600 catalog, allowing systems to use safety I/O directly.

The new CIP Safety module installed in the EX600. Image used courtesy of SMC

Industrial Safety I/O

CIP safety over Ethernet/IP has been used for many years now, especially with servo drives, to transmit safety communications over the popular industrial Ethernet network, EtherNet/IP. The new EX600 safety fieldbus module allows system designers to place safety I/O directly in the field near the actuators, valve banks, and systems that require them.

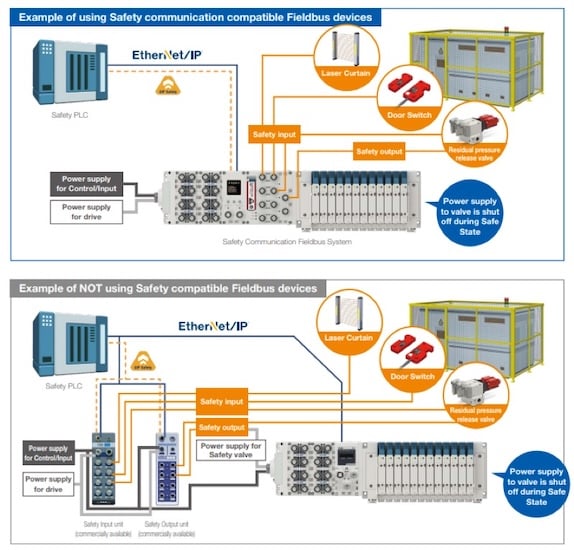

A typical installation of a pneumatic valve bank on a machine will require a constant 24 V DC source and a switchable 24 V DC power source. This switched power is routed through a set of safety relays that are energized with a safety output, and the state of the relays is monitored with the safety inputs. This topology requires extensive wiring and cabling from the main panel to all valve banks on the equipment.

With the EX600 safety fieldbus system, only 24 V DC and Ethernet communications are provided to the EX600. When a safety output is commanded off over the CIP protocol, power to the external output and/or valve bank is turned off, thus eliminating the need for safety relays and panel safety I/O systems. The EX600 uses a dual redundant output method and monitors the state of the outputs for constant diagnostics.

Two systems, one using conventional safety I/O and the other using the EX600 safety I/O. Image used courtesy of SMC

EX600 Safety Communication System

The safety module has a safe input and output module comprising 16 safety inputs and up to 2 external safety outputs. One output is used for internal safety control of up to 32 solenoid pneumatic valves; an upgraded model allows for up to 128 solenoid valves. The safety inputs can be used to check residual pressure in the system or light curtains. They can be configured as single or dual inputs, with dual reducing the total inputs by half.

Inside a factory that uses safety systems and pneumatics. Image used courtesy of Unsplash

A New Look At Machine Design

As more companies develop products that use the CIP safety protocol, machine designers must review how their machines are laid out concerning field I/O and safety I/O. Up until now, safety I/O has been hidden away in the control cabinet with relays and I/O cards. Still, with new products like the EX600 safety communication module, we can connect safety devices directly to our field I/O. This new topology can greatly reduce complex wiring, time-consuming troubleshooting, and field cable runs, making a cleaner and more efficient machine.