As factories adopt smarter equipment and wireless systems, cutting down on cabling and connection issues has become a real priority. SMC’s EXW1 and EX600-W wireless units tackle that problem by linking I/O modules, valve manifolds, and controllers without the usual tangle of wires. Now, SMC is extending the lineup with several upgrades that improve flexibility, stability, and data visibility, making the system easier to integrate into both new and existing equipment.

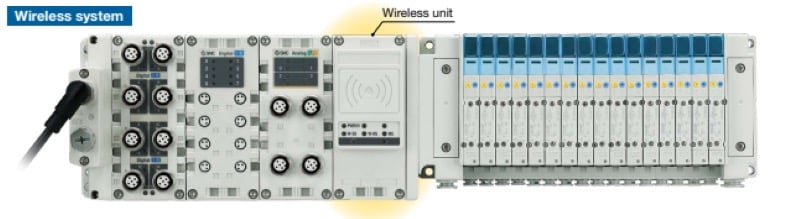

SMC’s EXW1 wireless communication system. Image used courtesy of SMC

Compact, Lightweight Wireless Communication

The EXW1 is the main unit in the lineup. It’s a compact wireless module that takes the place of normal fieldbus cables. It runs on the 2.4 GHz band and hops frequencies every two milliseconds to keep signals steady, even when other wireless gear is nearby. Its lightweight design (roughly 81% smaller and 79% lighter than previous models) minimizes load on moving components such as robot arms or automated carriers, where vibration and motion often limit wired systems.

For added installation flexibility, SMC now offers a DIN-rail mounting adapter (EXW1-AB5), allowing the EXW1 to be securely installed inside control panels or enclosures. This new option simplifies integration with PLCs and safety controllers, keeping the system protected from vibration and dust while reducing wiring clutter in tight control spaces.

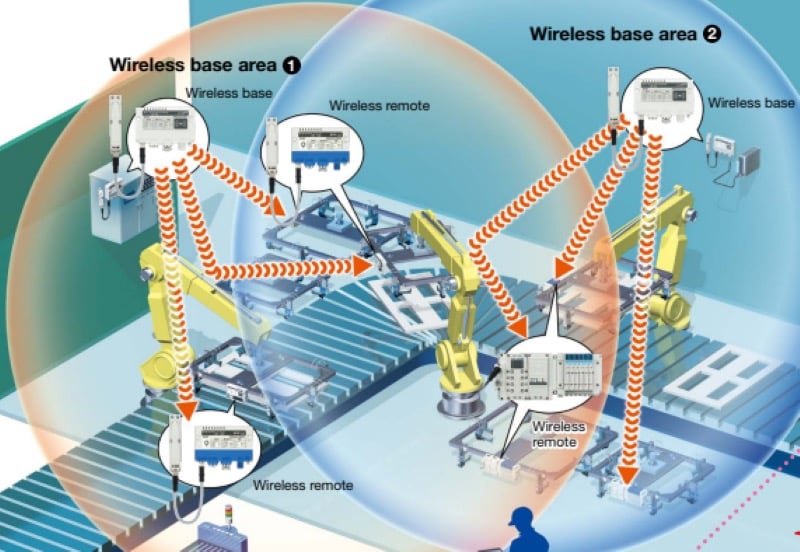

The EXW1 and EX600-W systems create stable wireless communication zones. Image used courtesy of SMC

Remote I/O and Valve Manifold Options

The EXW1 series supports a range of remote units that allow engineers to tailor setups to specific automation tasks. The EXW1-RDMPE3 remote I/O module adds timing measurement and log functions for valve operation counts and cylinder actuation cycles, a new feature aimed at preventive maintenance. These logs can help detect irregularities before a failure occurs, supporting continuous uptime and smarter maintenance planning.

For pneumatic applications, the EXW1-RDYM valve manifold combines high-speed wireless response with a compact footprint, roughly two-thirds lighter than comparable EX600-W units. It can be installed directly on moving equipment or robotic tooling, reducing the need for long air hoses and signal cables while maintaining precise valve control.

Noise Resistance and Wireless Security

SMC designed the EXW1 and EX600-W systems to maintain stable, interference-free communication even in dense factory networks. The F.C.S. feature lets users pick which wireless channels to use so they don’t clash with nearby systems like Wi-Fi, AGVs, or Bluetooth. Extra encryption keeps the data safe from interference or tampering while it’s being sent. These wireless design choices eliminate many of the failure points associated with cabling (including disconnections and wear) and reduce installation time and overall system cost.

Smarter Setup and Diagnostics

Configuration and maintenance have also been simplified with SMC’s latest software tools. Operators can use the new web interface or IO Configurator to watch signal quality in real time (things like RSSI, error counts, and retries) and save that data as CSV files for review later. SMC also added NFC setup through the EXW1-NT1 reader/writer so that users can pair and configure devices quickly without cables or a computer connection. Together, these diagnostic tools give maintenance teams greater visibility into network conditions and system health, supporting predictive maintenance strategies and reducing troubleshooting time.

Building the Wireless Factory

With compact form factors, advanced frequency management, and modular installation options, the EXW1 and EX600-W systems bring high-speed, noise-resistant communication to modern factory automation.