Bitmasked Automation has announced the release of the intelligent LevelCommand control system for monitoring and tracking stored materials in bins/tanks across agriculture, oil and gas, food and beverage, chemical, waste management, and manufacturing industries. The system uses hands-free radar technology and integrates with existing SCADA and PLC systems.

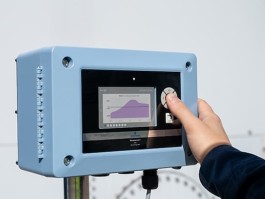

The three available models of the LevelCommand control system differ in the size of the interactive touch screen and sensor accommodation, ranging from 4 to 16 sensors. Image used courtesy of Bitmasked

A Solution for Multiple Industries

LevelCommand is designed for customers in the agricultural industry to monitor and manage liquid and bulk material levels with precision and ease. Whether it's grain in storage bins or silos or water and chemicals used in dairy and fresh produce operations, LevelCommand ensures you never run low, or risk overfilling. The system provides real-time alerts via text or email when levels reach critical thresholds, and its remote access features offer full visibility into operations, anytime and anywhere.

Beyond agriculture, LevelCommand is a powerful solution for industrial and manufacturing applications. It can monitor a wide range of fluids and solids, including chemicals, wastewater, and bulk materials, across water treatment plants, chemical processing facilities, oil and gas sites, and more, bringing the same level of reliability and automation to industrial environments.

An overview of how to configure and optimize your display of the LevelCommand V3.4.01 control system. Video used courtesy of Bitmasked

How Does it Work?

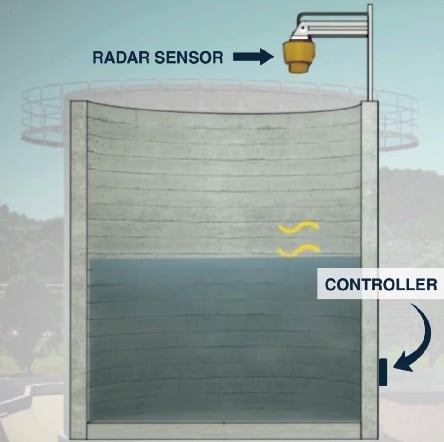

LevelCommand employs 80 gigahertz (GHz) radar sensors that transmit radio waves. These radio waves hit the surface of the solution. The radio waves bounce off, which is then picked up by the same sensor to detect the level in the bin/tank. Radio waves pass through dust, other particulate matter, and condensation, which would otherwise compromise capacitive and ultrasonic sensors. The radar sensor range options available are 25, 50, 100, or 400 feet.

Radar sensors offer a non-contact approach to solution measurement. Image used courtesy of Bitmasked

Users can configure and monitor control at a designated station next to the bin/tank or monitor operations remotely via a touchscreen on any device. Users also have the option to set up automated control of pumps, lights, alarms, augers, and more. LevelCommand is designed to incorporate a user-friendly interface, where customers can modify sensor names, set points, and colors for ease of use.

Benefits

While the device provides remote control and continuous visibility, another benefit includes added worker safety. The radar-aided measurement of fluid levels means that workers do not need to climb into and out of bins/tanks, which conserves effort and prevents the occurrence of unwanted accidents. This also frees up workers’ time to pursue higher-level tasks and mitigates the need for late-night emptying and filling. If workers do not need to be on site at late hours, this can help maintain a healthy work-life balance and optimize operational productivity.

Additionally, the radar technology eliminates the need for an in-tank/bin probe, which would require servicing and cleaning for continued operation and acquiring accurate readings.