Unitronics flexed its all-in-one muscles at PACK EXPO in Las Vegas, highlighting the flagship UniStream line of PLC+HMI control systems, an intriguing solution for the packaging industry. With integrated hardware, built-in cloud connectivity, and a unified development environment, UniStream systems are designed to ease the burden on packaging OEMs and end users. Today’s trends of simplicity, reduced downtime, and accelerated product changes all stand as a testament to an increasingly complex production landscape.

UniStream: The All-in-One Solution

Packaging operations are facing growing concerns in today’s market: shorter runs, varied SKUs, and requirements to provide traceability for products. In light of these trends, Unitronics’ booth demonstrations highlighted how the UniStream controllers are up to the tasks, including motor control, recipe switching, and remote system monitoring.

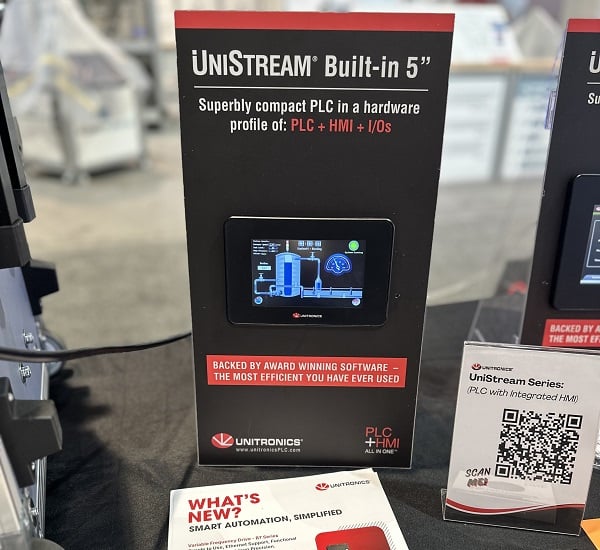

Each of these demo systems stepped through a realistic implementation, combining a PLC, high-resolution touchscreen HMI, and expandable I/O modules, all wrapped into a single platform. The systems showed the various models of the UniStream series, from small, self-contained systems up to those that support larger control systems with thousands of I/O points; a wide variety to meet numerous tasks.

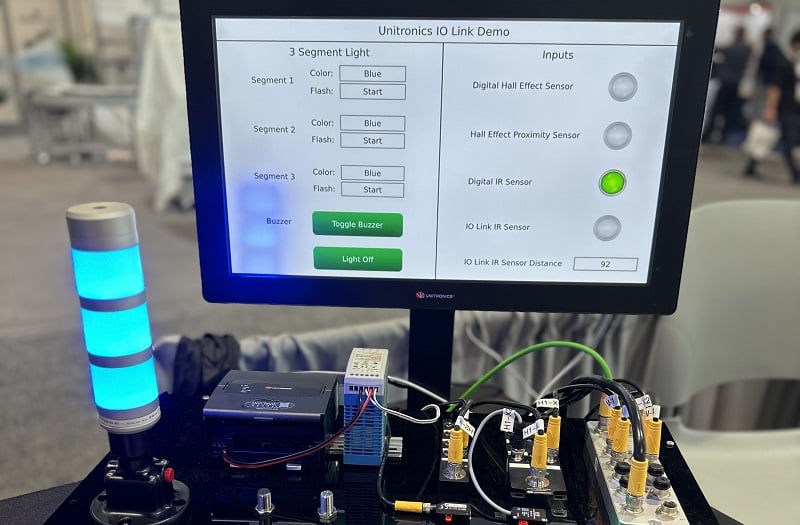

Unitronics PLC, motor, and I/O demo at PACK EXPO. Image used courtesy of Chris King, Unitronics

Aside from the integration of the PLC with the HMI, UniStream also provides support for UniCloud, Unitronics’ no-code IoT platform. The UniStream Cloud controllers can be securely connected to the cloud with simplified end-user configuration, providing quick access to data dashboards, machine statuses, alerts, and the ability to analyze data. These controllers come with a license included and no additional subscription cost for the service.

UniLogic Software

Any controller, no matter how reliable or user-friendly, is only as capable as its programming software. The Unitronics booth provided a great view into the UniLogic software platform, which is used to configure PLC hardware, write programs (across all IEC languages), design HMI screens, and connect to cloud services. Providing a single software portal for all of these applications can help to reduce engineering time and simplify troubleshooting. For this reason, it makes a great solution both for machine builders and for end users.

Setting up motion axes is another key application of the UniLogic software, providing a single portal from which all devices are configured and managed, including servo drives.

Unitronics I/O solutions on display at PACK EXPO. Image used courtesy of Chris King, Unitronics

Packaging Applications

PACK EXPO is all about packaging, and controllers take the center stage. In material handling applications like conveyor systems, indexing stations, and palletizing cells, UniStream’s high-speed I/O and flexible communication protocols allow systems to be integrated from various vendors. Additionally, support for a wide range of communication protocols, such as Ethernet/IP, Modbus TCP, and MQTT, ensures that UniStream systems can serve as a central controller, no matter what kind of peripheral equipment is running on the plant floor.

Unistream is the all-in-one hardware that integrates PLCs, HMIs, and more. Image used courtesy of Chris King, Unitronics

With the increasing embrace of so-called ‘smart’ technology and Industry 4.0 practices, it’s important to find products like the UniStream lineup that bridge traditional machine logic with forward-thinking edge and cloud capabilities. Unitronics’ presence at PACK EXPO this year underscores the company’s commitment to making advanced automation accessible, scalable, and easy to use for packaging professionals at every level.