WAGO’s updated 751-9402 Compact Controller 100 expands its role in connected automation, offering configurable I/O, dual RS-485 ports, and open software support. Built on real-time Linux with full CODESYS 3.5 compatibility, the controller bridges traditional PLC reliability and modern IIoT flexibility. Its compact DIN-rail housing saves space while supporting protocols like Modbus, MQTT, and CANopen®, making it ideal for distributed-energy, building-automation, and compact machine-control systems.

The new 751 Series Compact Controller 100 handles connectivity in a small package. Image used courtesy of Wago

Built for Complex, Space-Tight Systems

The new 751-9402 controller includes eight digital inputs and eight configurable channels to serve as inputs or outputs. Two analog inputs and two additional channels can be set for current or voltage, letting users scale the mix for each project. This flexibility removes the need for separate I/O modules in many small machines or energy nodes. Dual galvanically-isolated RS-485 ports connect to power meters, drives, and field devices over Modbus RTU. At the same time, full compliance with IEEE 2030.5, IEEE 1547, and SunSpec Modbus 700 makes it ready for distributed-energy and microgrid control.

The controller ships with a real-time Linux operating system and supports CODESYS 3.5 for standard IEC 61131-3 programming and open-source options such as Node-RED, Python, or C++. Engineers can even install Docker containers later for virtualization and edge-computing workloads. This mix of closed-loop reliability and open development freedom fits modern IIoT projects where custom analytics or web dashboards run alongside traditional logic control.

The Codesys V3.5 engineering tool provides libraries for motion, Modbus, and fieldbus integration. Image used courtesy of Wago

Design Focus on Practical Engineering

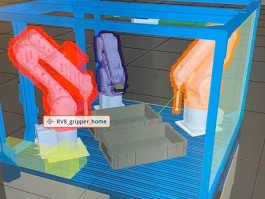

Housing the CPU and I/O in a single DIN 43880-compliant enclosure saves cabinet space and removes the need for separate expansion racks. A removable wiring interface makes swap-outs quick during commissioning or maintenance. The integrated mains filter and robust electrical isolation help the unit hold up against noise from drives and inverters, conditions common in renewable-energy installations and compact factory cells. Networking is equally straightforward. Two Ethernet ports allow line, ring, or star topologies; USB-C provides service access; and CANopen® connectivity expands its reach to existing fieldbus networks. HTML5-based visualizations come built through the web server so technicians can view process screens from a browser without extra software.

Software Environment and Cybersecurity

Real-time Linux lets users manage their software, handle updates, and set security rules as needed. The controller’s firmware also brings a built-in firewall and supports secure protocols like MQTT over TLS for connections to cloud or SCADA systems. Because it’s open-source friendly, the platform benefits from continuous community hardening and regular patch availability, which is important for long-lived energy systems and municipal infrastructure.

For engineers who prefer standardized environments, CODESYS V3 remains fully supported with motion, Modbus, and fieldbus integration libraries. Combining both options lets development teams decide whether to use classic ladder, structured text, or modern scripting languages within the same device family.

Applications Across Energy and Industry

The 751-9402 Compact Controller 100 targets distributed-energy resources, microgrids, and building-automation systems that require precision and communication with mixed devices. It also suits OEM machines, HVAC controllers, and test rigs where compact control and simple wiring are priorities. Engineers can standardize on one controller across projects ranging from small equipment to IIoT gateways, reducing spares and simplifying programming.

Outlook

WAGO’s upgrades turn the Compact Controller 100 into more than a small PLC. Configurable I/O, dual RS-485 interfaces, and support for industrial standards and open-source tools give designers a flexible platform for modern automation. The combination of real-time Linux and proven CODESYS control lets users match reliability with adaptability, which is exactly what current energy and manufacturing systems demand.