At the International Manufacturing Technology Show (IMTS) in Chicago, Siemens premiered MACHINUM, its new machine tool digitalization system designed to speed up machining times by 15%. As an added bonus, the quicker machining also results in less scrap or rework material and can extend the life of machine tools through real-time machine data monitoring and control.

Siemens’ new MACHINUM is a machine tool digitalization software portfolio designed to optimize machining. Image used courtesy of Siemens

Siemens’ MACHINUM

At its core, Siemens’ MACHINUM is a suite of software products designed to increase machining speed based on digitalization and optimization of machine assets. It provides seamless integration between machine tools, including both SINUMERIK and non-SINUMERIK-controlled CNC machines. Also, MACHINUM is adaptable and scalable to suit companies’ manufacturing and design needs.

MACHINUM helps users build a digitalization profile of the machining process and is integrated with Siemens Xcelerator. Xcelerator is an entire ecosystem made up of developers who can build hardware and programming solutions to meet the individual needs of the particular facility. Not only can Xcelerator be used to assess existing problems, it can be used to find and eliminate problems before they occur. In essence, it is a way to collaboratively solve complex optimization problems in the CNC machining sphere.

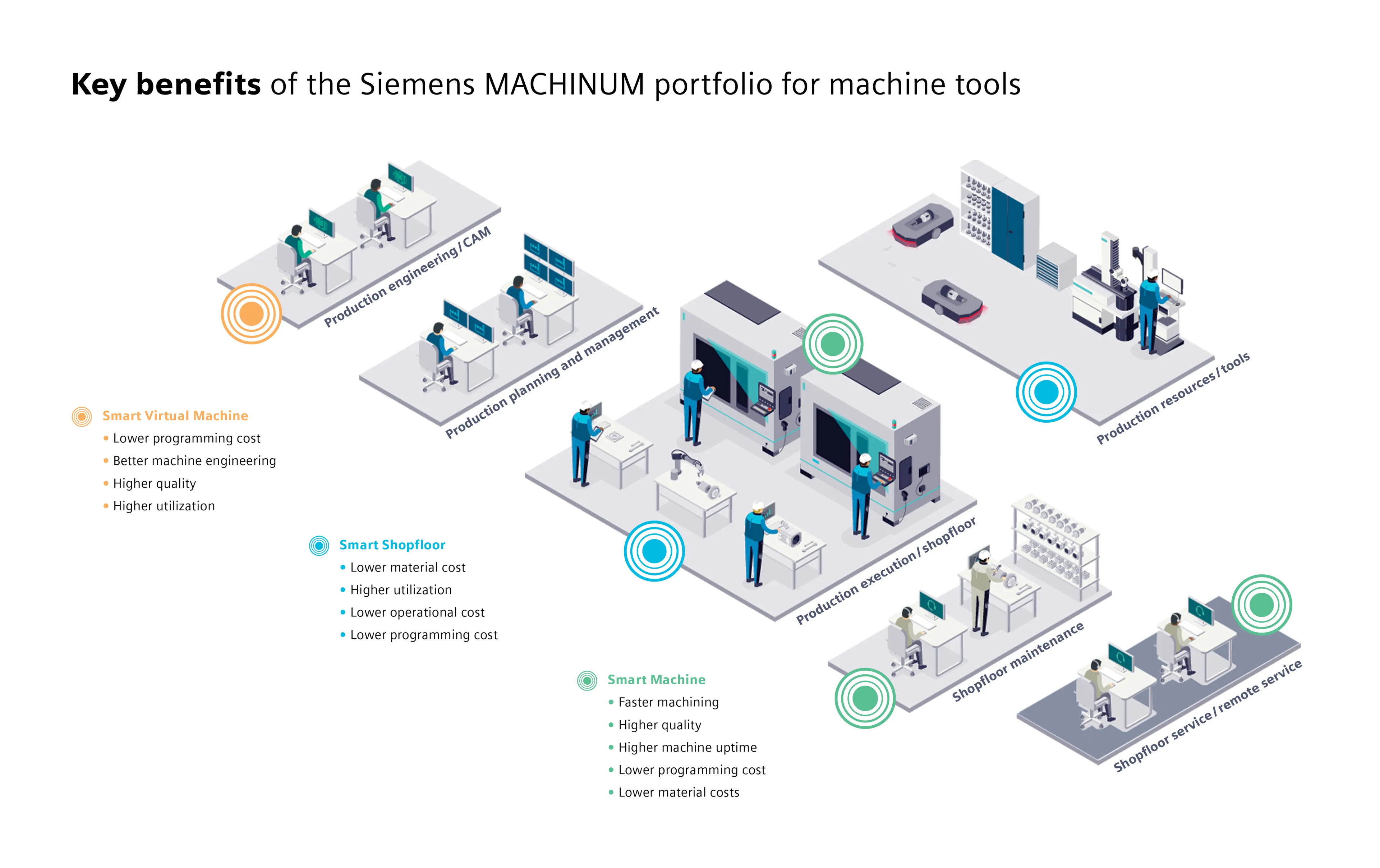

Siemens’ new MACHINUM portfolio consists of Smart Machine, Smart Shopfloor, and Smart Virtual Machine (click to enlarge). Image used courtesy of Siemens

A CNC Digitalization Software Portfolio

MACHINUM combines three sets of digital tools, including Smart Machine, Smart ShopFloor, and Smart Virtual Machine. These tools are built into MACHINUM to optimize speed, agility, and endurance of machine tool life and throughput.

Smart Machine

Smart Machine leads to lower production costs by boosting uptime and reducing material scrap, both in worn machine tools and waste material. This is made possible through real-time machine data and in-process control of machine tools.

Smart ShopFloor

The purpose of Smart ShopFloor is to handle real-world, real-time resource management. Too often, machines sit idle because they wait for a previous process to finish, goods to be transported, or some other such delay. Through more efficient resource planning, operating costs are significantly reduced and machine uptime is maximized.

Smart Virtual Machine

The optimization continues through Smart Virtual Machine. Smart Virtual Machine can leverage smarter data sources, such as digital twins, to ensure proper quality control has been achieved. Ultimately, this leads to fewer test runs, scrap, and rework, reducing operating costs, especially in components that require expensive raw materials.

MACHINUM is designed to bring increased machining speed and efficiency to its users. Image used courtesy of Siemens

Machine Tool Optimization

The two key benefits of MACHINUM are the ability to speed up machine throughput while also optimizing energy efficiency. Anyone can run a machine faster; what Siemens has done is bring optimization to these machines to run them as fast as makes sense in terms of throughput, planned maintenance times, and tool changes.

Dave Morely, mid-market sales manager at Siemens Digital, summarized MACHINUM, stating, “Siemens developed a digitization portfolio that drives increased usability and capability, and at a lower cost, to provide greater access to this technology. Companies that produce quality parts faster and more efficiently will continue to outcompete competition — and integrating MACHINUM can help them do just that.”