An ultrasonic sensor detects objects by transmitting a high-frequency sound wave and measuring the time it takes for that sound to return to the sensor. Ultrasonic sensors provide an advantage when trying to detect objects that have a highly reflective surface or are transparent. Recently, Carlo Gavazzi Automation released three new series of ultrasonic sensors: the UA12, UA18, and UA30, all with IO-Link.

Carlo Gavazzi’s UA12, UA18, and UA30 ultrasonic sensor series features integrated IO-Link communication. Image used courtesy of Carlo Gavazzi

Ultrasonic Sensors With IO-Link

The new series of ultrasonic sensors from Carlo Gavazzi are designed to detect difficult object surfaces in harsh conditions, thanks in part to the wide range of operating temperatures, from -25 °C to 70 °C, and the ability to resist interference from dust, fumes, and steam.

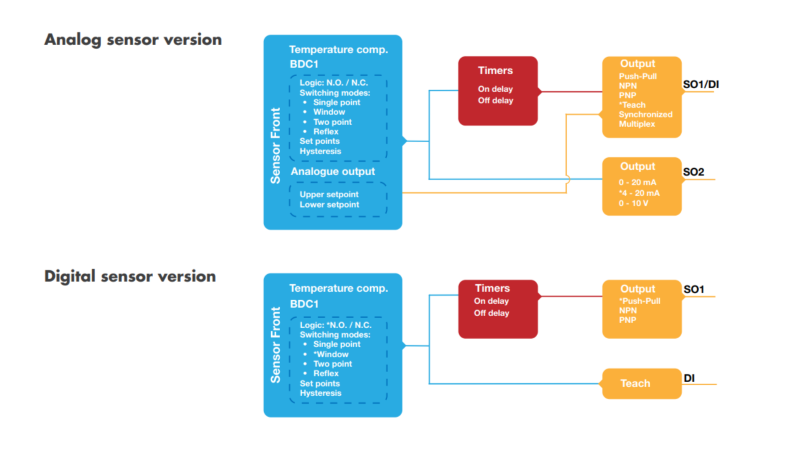

The sensors come in three sizes: M12, M18, and M30, all of which can be ordered as strictly digital-only output or combination output, one digital and one analog. Analog versions are 4 to 20 mA, 0 to 20 mA, and 0 to 10 VDC. The digital output can be configured as either push-pull, NPN, PNP, or Teach-in.

The sensing range is the distance from the sensor at which objects can be detected. The new sensors have a sensing range from 20 mm to 6000 mm, depending on the model chosen. Connection to the sensors is accomplished using a standard four-pin M12 connector, regardless of the sensor chosen.

The ultrasonic sensors’ IO-Link function enables parameters and functionalities to be configured according to application needs. Image used courtesy of Unsplash

Integrated IO-Link Communication

Analog sensors typically require special input cards and cables to get the signal back to the control system. This can cause troubleshooting issues and longer integration time, especially if using multiple sensors for one application. Sensors with IO-Link can be configured and taught, and the analog value can be monitored for further analysis. With the IO-Link models, users also get the digital output wire available if needed. Diagnostics also becomes easier with IO-Link thanks to the integrated diagnostics features of the protocol.

Ultrasonic Sensor Applications

There are many applications for ultrasonic sensors, and the fact that they double as a distance sensor adds even more applications. Level monitoring is a common application for ultrasonic sensors because they can detect the level of transparent fluids, and they don’t need to make contact with the fluid. They also have a wide operating temperature and are not susceptible to steam, so if a process requires heating of a fluid, an ultrasonic sensor might be the right choice. Detecting transparent plastic bottles is another common use, as a through-beam or diffuse sensor might have trouble detecting the transparent surface.

Example of a bottling line with clear plastic bottles. Image used courtesy of Adobe Stock

Sensor Selection

When selecting a type of sensor, you need to review your application and the surface you are trying to detect. Some applications might require some bench testing and trials to make sure your sensor will be reliable. There is nothing worse than a sensor that is flaky and not reliable. The ultrasonic sensors from Carlo Gavazzi offer an all-in-one solution with the integrated IO-Link, as you get both distance measuring and digital object detection.