Baumer’s company Hüber Berlin, known mostly for encoders and tachogenerators, has developed a new, simple-to-use digital cam switch. The PMG93 CAM features a rugged design for heavy-duty applications and boasts a simple setup and configuration to bring hoist and winch systems online quickly.

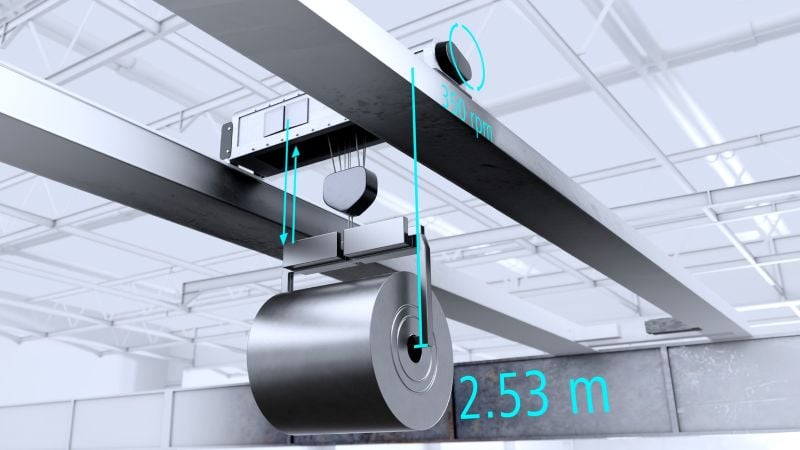

Baumer Hüber Berlin’s HeavyDuty PMG93 digital cam switch is designed to simplify heavy-duty hoist and winch applications. Image used courtesy of Baumer

What Is a Cam Switch?

A cam switch is a rotating set of electrical contacts that can be used to turn on a motor, pump, or other device when rotated. They allow multiple devices to start in a sequence as the cam turns and activates each set of contacts. This makes them great for ensuring a proper startup sequence of devices. Typically, cam switches can handle high currents. The rotating action and the high current handling capabilities make them suitable for crane and hoist controls.

Mechanical cam switches are subject to wear and tear due to heavy loads, vibration, shock, impact, repeated motion, and corrosion. Also, they can be challenging to program, as users need to determine the length of cable, rope, or chain that is spooled or unspooled with each rotation.

The PMG93 CAM’s straightforward configuration requires a laptop, Ethernet connection, and a web browser. Image used courtesy of Baumer

PMG93 CAM Digital Cam Switch

The PMG93 CAM is a digital cam switch branded under Baumer’s “HeavyDuty” portfolio, highlighting its suitability in harsh, outdoor industrial environments. According to Baumer, the switch has no mechanical parts, making it nearly immune to external wear from vibration and impact.

One of the key features of the HeavyDuty PMG93 is its quick and easy configuration. Changes to the system can be made quickly, with little downtime. Instead of using proprietary software and relying on technicians with specialized training, the PMG93 can be programmed with a web browser interface and an Ethernet connection. It is truly software independent, as there is no software, just a browser interface. Furthermore, no internet access is required, just an Ethernet cable and a laptop.

Each switch can be programmed using a “teach” mode, meaning technicians with little training can bring the cam switch online and perform properly. The digital parameterization and a wide assortment of mounting kits means that only one PMG93 is required for most applications. There is no need to buy multiple cam switches for different-sized hoists; one can be configured quickly for each. It can be used in new installations and retrofit and modernize existing hardware.

The PMG93 CAM can retrofit existing systems to replace mechanical cam switches. Image used courtesy of Baumer

Heavy Duty Applications

Baumer Hüber Berlin developed the PMG93 ruggedized digital cam switch for challenging environments. In particular, port facilities exposed to temperature extremes, moisture, salt spray, and other environmental factors will benefit from the PMG93. Besides ports, oil and gas industries, metals processing for scrap and foundry work, mining, and other outdoor materials handling applications are good markets for the PMG93 CAM.