Many industries, such as those that deal with pharmaceuticals or medical devices, often necessitate robust inspection methodologies that can also ensure product integrity and adherence to various industry compliances that are needed to get new customers. With traditional inspection systems, there is often a struggle to provide the required precision and traceability, which leads to potential quality deviations and regulatory non-compliance.

Introducing the Compact In-SIght 8900 Series from Cognex that features a fully embedded AI-powered vision system. Image used courtesy of Cognex

Cognex has recently introduced the In-Sight 8900, a self-contained, AI-driven vision system engineered to address these challenges. The In-Sight 8900 family was designed with advanced deep learning algorithms directly onto the hardware, eliminating the reliance on external PCs and controllers, which provides a localized, high-throughput platform for automated visual inspection capable of executing complex tasks with minimal latency.

So What Can The In-Sight 8900 Do?

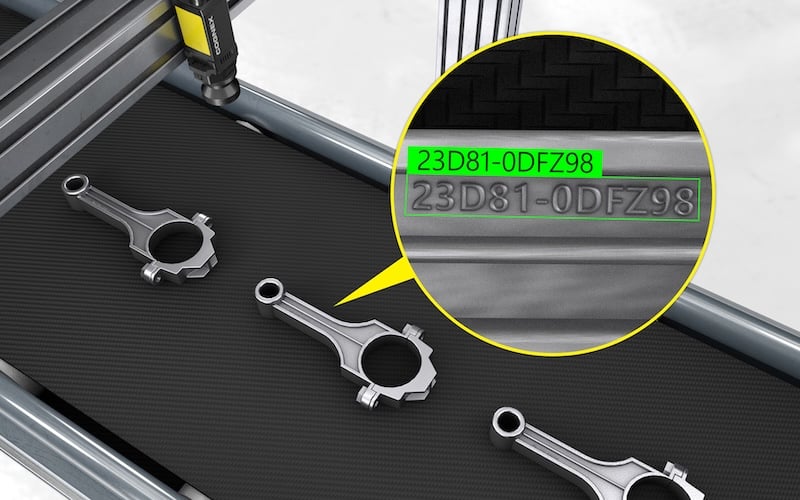

The IS-8900’s family core functionality gives end users the ability to automate a broad spectrum of inspection processes, such as precise defect detection, dimensional verification, and end-to-end traceability through barcode and optical character recognition. The AI software provides its users with real-time analysis, which allows users the ability to identify subtle anomalies that might escape traditional rule-based systems. Think of it: a system that learns and adapts to the specific nuances of a production line.

The In-Sight 8900 Series can detect defects, check the size, or even provide traceability through serial numbers, barcodes, or QR codes. Image used courtesy of Cognex

Does Your Company Operate Under 21 CFR Part 11?

For manufacturers operating under regulatory mandates, specifically 21 CFR Part 11, the In-Sight 8900 offers integrated compliance features such as audit logging that provides a comprehensive, time-stamped record of operator actions and enables meticulous traceability. Users will also have the ability for single sign-on (SSO) that utilizes Microsoft Windows

authentication, which simplifies user management and enhances security.

So What Are The Specs?

The hardware itself is designed for industrial deployment. The compact, die-cast aluminum and zinc housing, coupled with an IP40 rating, ensures robust operation in demanding environments. The In-Sight 8900 will also feature a high-speed liquid lens that is capable of sustained high-cycle operation and allows rapid, precise focus adjustments.

The In-Sight 8900 family will consist of (4) variations that will be available in either 9-bit monochrome (M) or 24-bit color(C), the IS8900 (SVGA), IS 8902 (2 megapixels), IS8905 (5 megapixels), and IS 8912 (12 megapixels). Depending on your applications, these image sensors can provide frame rates ranging from 10 fps up to 142 fps and working distances of 16 mm, 25mm, and 35mm. The system supports a range of industrial communication protocols, including PROFINET and EtherNet/IP, enabling machine builders to integrate more easily with a variety of different communication protocols.

Cognex also provides users with a software suite that combines AI-driven edge learning with traditional rule-based tools, which allows for a flexible application architecture capable of adapting to some of the most complex inspection tasks. You might have a line where you need to check tiny dimensions and another where you have to read text that's been distorted; this system can handle both. By embedding AI directly into the In-Sight 8900 series industrial-grade vision system, Cognex provides a solution that addresses the key needs of high-precision manufacturing: product integrity and regulatory compliance.