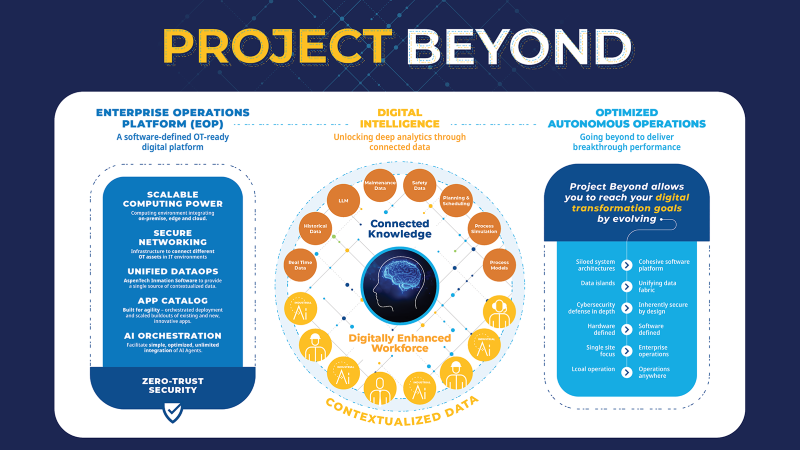

Emerson has created a new, software-defined operational technology (OT) platform capable of bridging many existing automation and control systems. Project Beyond is a scalable, artificial intelligence (AI) enhanced system that aims to revolutionize automation in industrial environments.

Emerson’s Project Beyond is an enterprise operations platform designed to modernize automation. Image used courtesy of Emerson

Emerson’s Project Beyond

According to Emerson CEO Ram Krishnan, the Project Beyond enterprise operations platform “...will use the power of software-defined control to introduce an entirely new, scalable, seamlessly integrated infrastructure with automated data contextualization to turn trapped data into powerful operational efficiencies.”

The reality is most organizations collect much more data than they can process manually or even with some assistance from computers. In the old days of manufacturing, sensors were expensive and data-limited. In the modern era, the “big data” era, sensors are affordable, and data storage and processing capabilities are limited.

Are there subtle signals hidden between process variables that are hard to see? Project Beyond can be used to find these signals and take corrective action. Data that is siloed in traditional control systems can be accessed, analyzed, and contextualized to find these trends.

Project Beyond enables users to integrate industrial AI and data analytics into operations from one platform. Image used courtesy of Emerson

Enterprise Operation and Optimization

Project Beyond implements several other Emerson products and combines them into one complete package, ready for quick deployment in the field. Its roots stretch back to Emerson’s Boundless Automation vision, geared toward edge and cloud computing, with data unification as a major component. It also has ties to Emerson’s DeltaV distributed control system and AspenTech’s advances in AI.

“By combining Emerson’s automation capabilities with AspenTech’s deep software expertise — from modeling to machine learning and AI — we’re embedding artificial intelligence into our systems, turning information into insights that will help our customers along their journey towards optimized, autonomous operations,” Kirshnan explained.

Key components of Project Beyond include computing capability, network connectivity, data management, an app marketplace, AI orchestration, and security. Project Beyond leverages AI and the unification of edge computing and control systems to ensure reliable communication between systems. From there, data is analyzed and contextualized so that control logic can optimize the process.

Project Beyond utilizes zero-trust cybersecurity architecture to ensure secure operation. Image used courtesy of Emerson

A Secure and Scalable Platform

Data management and integrating systems have a major challenge: security of data. Process data is ripe for cyberattacks, either through ransomware, industrial espionage, or other such threats. Included in the Project Beyond arsenal is Zero-Trust Security Architecture that ensures only relevant parties can access this data.

By integrating control systems and unifying data, this system is inherently scalable. Should there become a need for more controllers, Project Beyond can integrate them into the existing system. This aims to save time and effort so that systems engineers no longer need to either live with unintegrated systems or redesign the entire automation system when new needs arise.

Beyond… Project Beyond

Emerson has designed Project Beyond’s software-defined OT to be an industry first. It allows engineers to add value to their process lines without adding new complexity. It makes more data available and accessible without the need to replace existing control systems. Emerson hopes that it will open the door for new possibilities in automation, some of which may not be fully realized until its widespread deployment. The full impact of Project Beyond and the possibilities it creates will grow as more engineers take advantage of this technology.