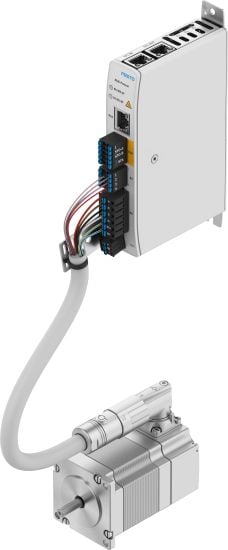

Festo has released the CMMT-ST servo drive starter kit that serves as a cost-effective way for customers to learn how to set up and size Festo’s multiprotocol servo drives. The new developer’s kit combines Festo's CMMT-ST servo drive with an EMMT-ST stepper motor at 50% of the cost of purchasing parts individually.

Festo’s new developer’s kit includes a CMMT-ST servo drive and an EMMT-ST stepper motor. Image used courtesy of Festo

CMMT-ST Multiprotocol Servo Drive

Festo’s new CMMT-ST servo drive starter kit includes the CMMT-ST servo drive. This servo drive features multiprotocol functionality and is configurable as EtherCAT, Modbus TCP, PROFINET, and EtherNet/IP to accommodate integration with different PLC brands. The CMMT-ST servo drive features a compact, space-saving form factor, secure cloud connectivity, and rapid commissioning with Festo Automation Suite, as well as safety features (safe torque off) for safe operation during maintenance or for emergency stops.

Festo’s CMMT-ST multiprotocol servo drive is configurable as EtherCAT, Modbus TCP, PROFINET, and EtherNet/IP. Image used courtesy of Festo

Festo’s CMMT-ST Starter Kit

More specifically, Festo’s CMMT-ST servo drive starter kit includes the CMMT-ST 300 W servo drive and the EMMT-ST stepper motor (with a battery-less, multiturn, absolute encoder), along with a motor cable and connectors. One of the key highlights of the starter kit is its affordability: the kit is priced at half of all the individual parts combined. The low-cost combination of the CMMT-ST 300 W servo drive and EMMT-ST stepper motor enables developers to try their hand at commissioning and sizing the parts.

Festo’s CMMT-ST starter kit enables quick and easy commissioning with Festo Automation Suite. Video used courtesy of Festo North America

The developer’s kit includes QR codes that connect users to the Festo Automation Suite for quick and easy commissioning and to Festo’s Electric Motion Sizing software to help users pick specific parts. Users can customize the setup by logging in and selecting their desired communication protocol from a drop-down menu. All models within the CMMT servo drive family use a function block programming approach.

With block programming, users can visually set motion control, communication, and safety features by using pre-defined function blocks rather than raw code. This approach streamlines setup for Festo's CMMT servo drives by offering common motion control instructions that apply to the whole CMMT family, such as positioning, velocity control, and homing. Customers can use a drag-and-drop interface to deposit blocks into a logic sequence, negating the requirement for ladder logic programming or intricate text.

Optimized Motion Control

The CMMT-ST multiprotocol servo drive can be employed in several industrial settings where accurate motion control is necessary. The compact drive maximizes control cabinet space while enabling exact motions for filling, sealing, and labeling operations in packing machines. It offers high-precision positioning in automated assembly and handling to increase productivity and uniformity. It is designed to help customers facilitate the accurate placement of parts and testing in the electronics sector.

Additional uses include textile manufacturing, where the drive can coordinate motion patterns in knitting and weaving operations, and medical technology, where it can be employed for positioning in surgical instruments and imaging devices. Ultimately, Festo’s CMMT-ST drive can be flexibly integrated into different industrial application projects because of its small form factor and multiprotocol compatibility.