Hilscher’s netFIELD app delivers a straightforward way to integrate Modbus RTU/TCP devices with MQTT-based IIoT platforms, enabling IT and OT to work in sync. As a platform-independent software container, netFIELD converts Modbus data into lightweight MQTT messages, which are ideal for low-bandwidth industrial networks. With unlimited device support, built-in Modbus proxying, and intuitive JSON-based configuration, the app offers scalable, real-time connectivity that improves uptime, enables predictive maintenance, and simplifies both new installations and system retrofits.

Integrating Modbus and MQTT

The netFIELD app acts as a platform-independent software container. As such, it allows for the quick conversion of Modbus data into Message Queuing Telemetry Transport (MQTT) protocol. The primary advantage of doing so is that many IIoT devices use MQTT, which is lightweight, open, and simple. As many IIoT devices end up on low-bandwidth, high-latency, electrically noisy networks, MQTT is a good choice for relaying data.

The netFIELD app makes adapting between Modbus and MQTT easy and simple. Image courtesy of Hilscher

netFIELD Capabilities

This new app facilitates integration between Modbus RTU or TCP servers into an MQTT message bus. The intuitive web-based user interface (UI) allows technicians to upload JSON-encoded Modbus description files that contain coil configurations, registers, and other relevant information about the devices and sensors. The files also contain information about how to read and write to the devices so that messages to them can be handled appropriately.

There is also a built-in proxy function that can translate between Modbus RTU devices and Modbus TCP clients. Sometimes, some server applications only support the Modbus TCP protocol and need to access or write to devices configured for Modbus RTU. With the netFIELD app, such conversion can occur with little input from the user.

Perhaps the most important advantage is that netFIELD does not limit the number of supported devices or the volume of data sent or received. This means netFIELD is readily scalable; new devices can be added and easily integrated into the existing system. Whether it is implemented at the beginning of a new process or is used to retrofit an existing system, there is always room for future expansion.

How it Works

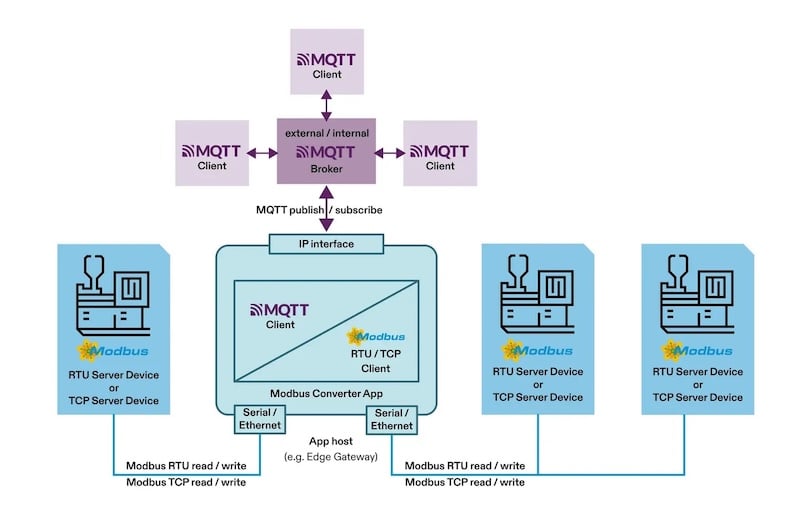

First, the app’s host is connected to the Modbus devices through its wired ports. From there, the app reads and writes data periodically, based on the configuration files. Data exchange is sent to the user as MQTT messages through the UI, so that they can make data-driven decisions. Adjustments to the process can be made through the UI as well.

The netFIELD app acts as a central piece, integrating Modbus RTU/TCP devices with MQTT. Image courtesy of Hilscher

The end result is that communication between devices is improved. Faster response times and increased productivity through real-time data analysis are now possible. From there, preventative maintenance tasks can be scheduled based on data-driven decisions instead of through usage or elapsed time, reducing unscheduled downtime. Overall, machine utilization and uptime are increased.

Applications

Modbus is widely used in the energy sector and other industrial or manufacturing industries. In power generation and distribution, more IIoT-capable sensors, edge computers, and smart control hardware are added every day, and integrating these new systems with Modbus can be challenging. Through the use of the netFIELD app, this process is drastically simplified, as it is platform-independent and performs much of the integration behind the scenes.