Factories around the world are under growing pressure to increase speed without sacrificing accuracy. Whether it’s an automotive plant tracking parts through every assembly phase or a food packaging line firing off hundreds of units a minute, barcode misreads slow everything down. And worse, they can lead to waste, rework, or missed deadlines. That’s where Omron’s latest innovation comes in. The VHV5 Ultra-High Performance Barcode Reader is engineered to eliminate the complexity and guesswork associated with industrial code reading. With a host of automated features and a compact form factor, this fixed-mount reader can handle everything from hard-to-read laser-etched marks on engine components to high-speed labels whizzing down consumer goods conveyors.

The VHV5 barcode reader helps eliminate barcode misreads. Image used courtesy of Omron

Automated Setup That Works in Seconds

At the heart of the VHV5 is its automated intelligent setup system. This isn’t just marketing jargon; it’s a real shift in usability. From the moment it’s powered on, the reader adjusts lighting conditions, locks in focus, learns all visible barcodes, and enhances image quality automatically. These steps, which once required fine-tuning from trained technicians, now happen in seconds. As a result, line operators can deploy the device quickly, with minimal training and virtually no calibration delays.

And it’s not just about ease of use; the VHV5 delivers serious performance. The reader’s two available sensor options include a 2.3-megapixel global shutter running at 80 frames per second and a 5-megapixel option at 40 frames per second. These are paired with a high-end quad-core processor and a built-in neural processing unit (NPU), allowing near frame-rate code reading for even the most demanding applications. Combined with Omron’s X-Mode 6.0 and Smart Assist technologies, the system can extract clear, scannable data from even degraded, scratched, or oddly positioned marks.

Durability, Compatibility, and Upgrade Simplicity

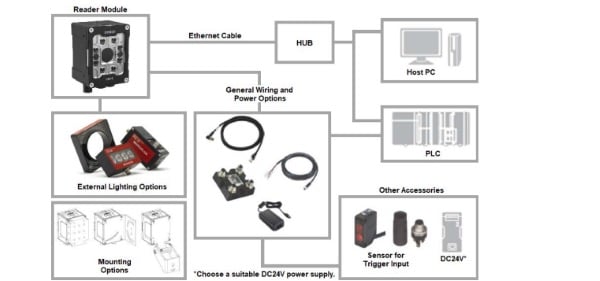

The hardware isn’t just powerful, it’s adaptable. The VHV5 is IP69K-rated, making it resistant to dust, water, and high-pressure cleaning. Its design includes options for multiple focal lengths and a third port for external lighting, compatible with most major machine vision suppliers. It supports a range of industrial communication protocols, including Ethernet/IP and PROFINET, as well as serial and digital I/O, ensuring seamless integration with a broad variety of factory control systems.

The upgrade path is also crystal clear. For companies already using Omron’s MicroHAWK V430-F and V440-F readers, the VHV5 offers plug-and-play compatibility. Wiring, mounting, and accessories carry over, meaning companies can scale up performance without needing a full system overhaul. Meanwhile, the inclusion of Power over Ethernet Plus (PoE+) or direct 24V power options offers installation flexibility that suits nearly any deployment scenario.

Omron’s barcode readers offer several runtime configuration options. Image used courtesy of Omron

Cross-Industry Versatility with Sustained Performance

Versatility is another core strength. The VHV5 is purpose-built for industries as diverse as automotive, mobility, packaging, logistics, and food production. In the automotive industry, it provides reliable direct part mark reading and barcode grading, supporting traceability from start to finish. In consumer goods, it keeps pace with blistering production speeds while delivering accurate, in-line label grading for quality control. Even in rugged logistics centers, where scanning is constant, the VHV5 maintains performance without overheating or losing accuracy.

A Fast, Reliable Tool for Modern Manufacturing

Barcode accuracy is no longer optional in high-throughput industries, and setup delays are a luxury no one can afford. With its high-speed processing, intelligent automation, and rugged design, Omron’s VHV5 barcode reader removes barriers to performance, giving manufacturers a fast, reliable, and user-friendly tool that keeps production moving and errors in check.