In today’s packaging lines, success depends heavily on reliable identification at a rapid speed. As demands on product variety and traceability keep growing, technologies like RFID verification and sensing must also keep growing in importance. At the recent PACK EXPO show in Las Vegas, Turck captured these concepts in its booth to demonstrate the advances in packaging automation with all-new levels of reliability, flexibility, and data insight.

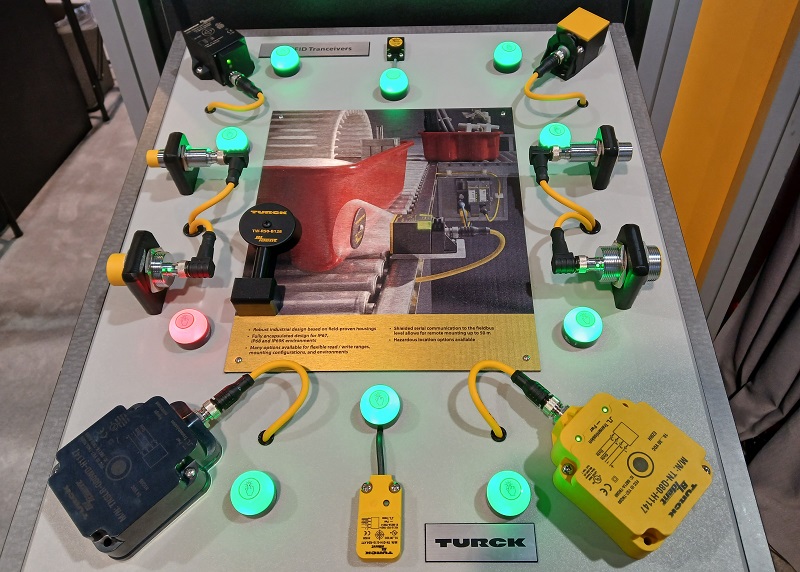

RFID for Tracking and Verification

RFID uses wireless short-range communication for tasks like track‑and‑trace, anti‑counterfeiting, and in‑line package identification. You may have used this technology at your local library, where RFID tags are often used to replace printed barcodes for faster checkouts. Turck has a long history in RFID technology, which includes low, high, and ultra-high frequencies (LF, HF, and UHF) read/write heads, tags, and middleware support.

RFID has several primary uses in logistics and packaging. When placed strategically, tag reading gates can scan incoming and outgoing packages from docks and warehouse doors, and, unlike barcode readers, they don’t need a perfect line of sight to each tag. Mobile devices, like AMRs and forklifts, can also be equipped with RFID readers to ensure that product tracking is accomplished while the packages are moving around the facility. The technology can also greatly accelerate inventory control in a warehouse.

RFID, as well as process sensing technology, is very important for packaging.

Sensing for Process Automation

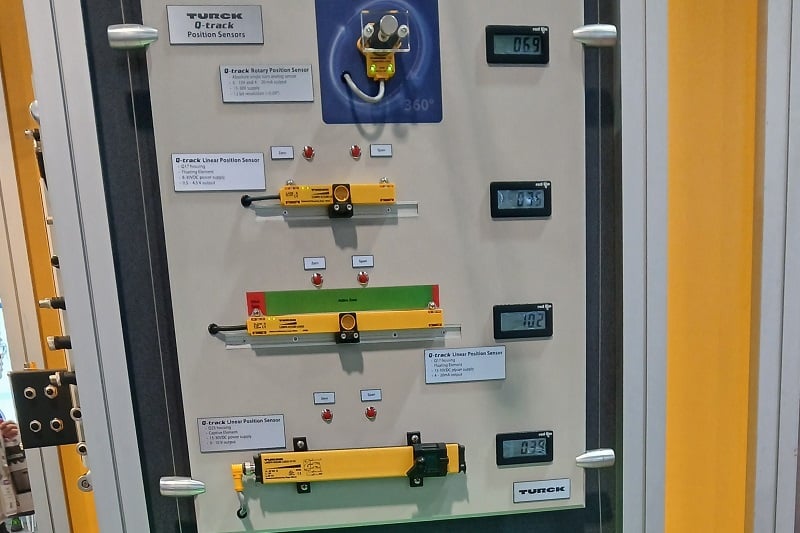

Turck also produces sensors for monitoring and detection applications within packaging systems. These sensors can detect the proximity of objects (discrete quantities) using principles of capacitance, inductance, ultrasonic sound, radar, and more. Analog sensors include pressure, level, temperature, flow, and more. Sensors are critical in most process applications to acquire data for alarms, fill controls, or feedback loops.

Turck has a wide range of rotary and linear position sensors.

Distributed I/O and Controls

The various demonstrations of individual technology pillars are bound together with a catalog of distributed I/O products and control modules. Turck offers a wide range of in-cabinet and machine-mountable block I/O systems with support for nearly all modern protocols: PROFINET, Modbus, Ethernet/IP, IO-Link, EtherCAT, and others. These modular I/O blocks are intended to be installed close to actuators and sensors, either inside the machine cabinets or directly on the machines themselves, saving the installation time of long wiring back to a central cabinet.

Sensing devices are the backbone of all I/O systems, either in-cabinet or on-machine.

Connectivity: the Future of the Packaging Industry

Turck’s PACK EXPO booth presented a solid example of today’s packaging line; not just the conveyors, sensors, and simple actuators, but an entire cohesive network that keeps the line running smoothly.

By combining RFID verification, level detection, and distributed I/O, Turck eases the burden for integrators and end users across the packaging and logistics landscape. The progress toward modular, intelligent devices is certainly spreading across the industry, and Turck is ready to help those next‑gen packaging systems become increasingly flexible, transparent, and efficient.

All images used courtesy of the author.