Noark Electric has expanded its catalog with the Ex9VF7 variable frequency drive launch, designed to deliver reliable, intelligent motor control across a wide range of industries. Featuring DSP-based precision, reduced noise operation, and support for major communication protocols like BACnet, Modbus, CANopen, and Ethernet/IP, the Ex9VF7 is built for flexibility. Covering power ratings from 0.25 to 250 HP, the drive supports applications from HVAC systems to industrial automation, giving OEMs and contractors a versatile solution.

The Ex9VF7 VFD from Noark. Image used courtesy of Noark

The Ex9VF7

A VFD is a common electrical device that controls the speed of an AC motor. These drives are commonly found in HVAC systems for fan speeds or in automated factories to control the speed of a conveyor. The Ex9VF7 is a new VFD from Noark Electric with cutting-edge features. The brains behind the Ex9VF7 use DSP technology, which allows the drive to precisely control the motor's speed for critical applications. Noise in a factory can be a safety concern, so the Ex9VF7 uses a carrier wave oscillation, which greatly reduces audible noise, yet still provides a high startup torque. For the Ex9VF7 to be used in the U.S and Canada, it must meet specific UL standards. Noark reports that the Ex9VF7 does meet UL 61800-5-1 standards. Industrial protocols are used to communicate with devices, so to stay competitive in the market, Noark has included BACnet, Ethernet/IP, CANopen, and Modbus, some of the most popular control protocols in use today. The Ex9VF7 comes fully equipped with all these features and the ability to add customizable I/O for specific applications. Covering power ranges from 0.4kW to 185 kW or 0.25 HP to 250 HP, and operating voltage from 110VAC single phase to 600VAC three phase, the Ex9VF7 can be utilized in virtually any application.

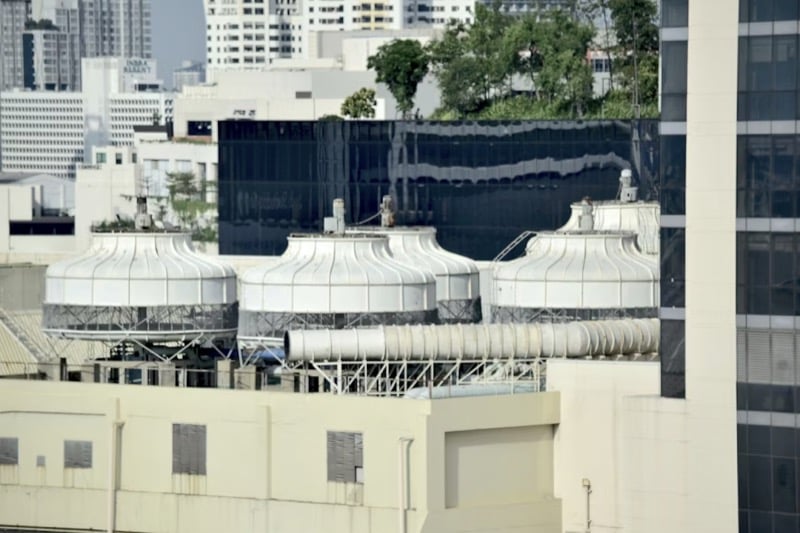

Roof-top air handling units with large cooling fans. Image used courtesy of Unsplash

Intelligent Motor Control

Controlling an AC motor is more complex than it used to be. Today, we require accurate speed control with high starting torque to use motors more efficiently. By using a VFD, such as the Ex9VF7, we can reduce motor starting torque draw, which results in less energy to perform the same action. The HVAC industry utilizes this feature the most with cooling fans. When the air handling unit is not in use, the fan shuts off, and when there is a call for air, the fan kicks on. A VFD in this application can reduce the current required to start the fan.

By using a VFD with intelligent speed controls and communication protocols, a PLC can ramp up and down speeds as required by the environment and record run times for preventative maintenance.