3D printing is no longer just for prototypes. Researchers in Europe and the U.S. are using it to tackle two major challenges: the growing issue of plastic waste and the development of new types of robots. What ties these innovations together is a single tool: the 3D printer. In Germany, scientists are transforming household plastic packaging into filament for printing durable parts. Meanwhile, in California, a team has created six-legged robots that can walk, without electronics, right off the printer. These breakthroughs are changing 3D printing from a creative tool into a practical manufacturing solution with real-world impact.

3D printers have been used to make many useful or recreational things, but what advancements are being made? Image used courtesy of Adobe Stock

Turning Trash into Print-Ready Filament

Every year, Germany generates around 5.6 million metric tons of plastic packaging waste. Most of it is single-use, and less than a third is recycled, which means the rest will most likely end up in landfills. However, a partnership between the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) and Hochschule Bremen is turning this plastic waste into an opportunity.

Their work focuses on polypropylene waste, which is commonly found in household packaging. The plastic is sorted, ground, washed, and processed with near-infrared technology to remove contaminants. The result is a clean feedstock with purity levels above 99.8%.

Every day, plastic trash is being melted down, mixed, and extruded into filaments to be used in 3D printers. Image used courtesy of Fraunhofer

Fraunhofer IFAM then takes over. Using an industrial extruder, they melt and reshape the plastic into smooth, consistent strands that can be used directly in commercial 3D printers. So far, their early prints have produced functional parts, including plastic caps.

There’s more to come. Plans include adding reinforcements like glass fiber to the recycled filament, making it suitable for high-performance applications in industries such as automotive or aerospace. With increasing regulations requiring more recycled content in plastic packaging, the demand for solutions like this is only growing.

Robots That Walk with No Electronics

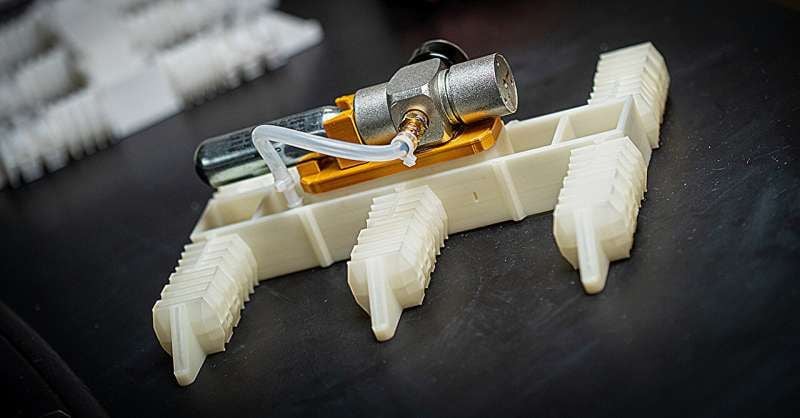

Meanwhile, in San Diego, researchers have taken a radically different approach to robotics. The Bioinspired Robotics Lab at the University of California, San Diego has developed a walking robot that doesn’t need electronics, motors, or batteries.

As long as the robot is connected to an air supply or gas that is under constant pressure, this 3D-printed robot can continue nonstop for up to 3 days. Image used courtesy of Techxplore

The robot, printed entirely from a single flexible material, is powered by compressed gas. A pneumatic circuit, similar to a miniature steam engine, controls the movement of its six legs. The robot alternates air pressure between two sets of legs to create a walking motion. This unique robot has proven that it is capable of walking on almost any surface, including turf or sand, and even moving underwater. It’s a promising solution for environments where electronics can’t function, such as in disaster zones or high-radiation areas.

The materials used for the robots are simple: standard 3D printing filament with no special modifications. However, the team worked with BASF to test both commercially available and experimental materials. The next steps for these unique robots will be finding ways to store gas inside the robots and using recyclable or biodegradable materials. The team is also looking into adding manipulators, like grippers, to the robots.

A New Approach to 3D Printing

These unique 3D-printed projects are demonstrating a shift in how we approach 3D printing. Whether it’s turning waste into useful materials or creating robots that function without electronics, 3D printing is opening new possibilities for many industries and research. From repurposed plastic to robots that walk without wires, 3D printing is transforming industries and solving problems in unexpected ways.