Getting precise distance data is one thing. Getting it into your control network without jumping through hoops is another. That’s where the addition of native PROFINET support in Pepperl+Fuchs’ R1000 distance sensor helps, by delivering fast, synchronized communication that fits right into real-world industrial setups, without extra converters or workaround wiring.

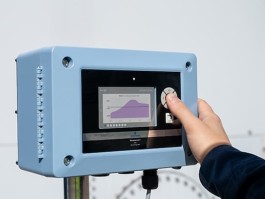

The R1000 sensor lineup now includes models that support the PROFINET interface. Image used courtesy of Pepperl+Fuchs

Why PROFINET, Why Now?

With the latest R1000 distance sensor variants, Pepperl+Fuchs adds native PROFINET support and an integrated switch, making it easier for engineers to incorporate high-precision sensing into distributed PLC systems. Whether running a high-bay warehouse, an automated shuttle, or a dual-axis crane setup, this version reduces the networking friction while retaining everything the R1000 family is known for.

Built for Harsh Environments

At its core, the newest models are still an R1000-class sensor, meaning they bring pulse ranging technology (PRT) with consistent <1 mm repeat accuracy across a measuring range of up to 300 m. The sensor operates using a visible class 1 red laser that simplifies alignment, especially when installing in hard-to-access locations.

Additionally, the sensor’s housing is compact, measuring only 81 mm in depth, and is IP67 rated, so it fits easily into tight spaces and holds up against dust and moisture. Built-in metal-threaded inserts let users mount the sensor directly without needing extra brackets, which is useful in short-range installations or places with a lot of vibration. For long-range setups that need fine alignment, Pepperl+Fuchs provides optional adjustment accessories to help dial it in.

Dual R1000 sensors can enable real-time anti-skewing control in overhead cranes via precise PROFINET-linked position feedback. Image used courtesy of Pepperl+Fuchs

Precise Distance Measurement

Keeping Cranes Centered

In overhead crane systems, slight skewing between the trolley's left and right movement can lead to drift, misalignment, or mechanical strain. With one sensor mounted per side, the R1000 allows for active skew compensation in the y-axis while tracking long x-axis movements. Combined with the real-time feedback provided by PROFINET, this setup enables reliable anti-skewing logic without introducing latency or jitter into control loops.

Automated Parking and Shuttle Positioning

In automated parking systems where space is tight and accuracy matters, shuttles need to be in the right position to prevent unnecessary damage to components. The R1000’s small footprint and precise, non-contact measurement help make that possible. Now that the sensor is available with native PROFINET support, it can plug directly into the building’s control system, streamlining data flow, diagnostics, and wiring.

R1000 sensors are capable of withstanding harsh electroplating conditions while delivering stable distance measurements. Image used courtesy of Pepperl+Fuchs

Chemical and Wet Environments

In electroplating plants, sensors must deal with high humidity, corrosive vapors, and long linear tracks. This R1000 variant is already proven in such roles, where multiple units must work in parallel without interfering. Thanks to PRT’s sharp light spot geometry and the sensor’s resistance to dirt and ambient light, the system stays stable even in less-than-ideal conditions.

PROFINET Meets Precision

The R1000 distance sensor, now available with PROFINET, is designed with engineering priorities in mind. Its precise distance measurement, direct integration with PROFINET systems, and robust mechanics are suited for industrial use. Additionally, the sensor’s combination of millimeter accuracy and native Ethernet support helps reduce setup time and makes it easier to incorporate into complex automation environments.