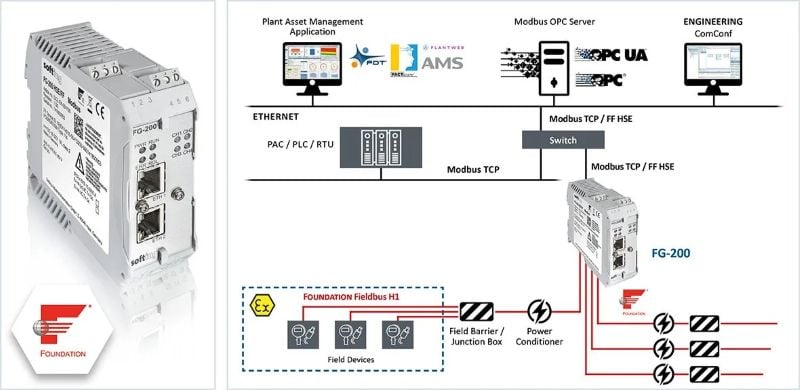

Softing Industrial has released version V1.21 of the FG-200 gateway. This gateway is designed to offer reliable connectivity to Foundation Fieldbus H1 (FF H1) devices for Ethernet-based control systems. The FG-200 is capable of connecting to up to four FF H1 field devices and acts as a bridge between these devices and the rest of the network.

The FG-200 gateway has been updated to version V1.21 for enhanced communication and reliability. Image used courtesy of Softing Industrial

Foundation Fieldbus (FF H1) Devices

Softing’s FG-200 gateway is capable of connecting to four FF H1 devices. FF H1 is a bidirectional communication protocol that allows each device to connect to up to 32 nodes. At first glance, the ability to connect to four FF H1 devices does not sound like many—the reality is that each of those can connect to up to 32 nodes. Therefore, one FG-200 gateway can handle over 100 separate nodes, sending and receiving data and managing all of the routing, timing, and other key parameters.

The FG-200 also allows simultaneous asset management using Modbus TCP or FF HSE. Asset management enables the use of software tools, such as Emerson’s AMS Device Manager and field device tool-based applications.

An added bonus: FF H1 can be configured with intrinsically safe wiring. The term intrinsically safe means electrical energy is contained such that there is very little chance of arc flash during changes of state. This is an essential feature for devices that will be near flammable vapors, such as those found in refineries, natural gas and oil wells, chemical production, and other similar industries.

The FG-200 gateway can connect to four FF H1 devices. Image used courtesy of Softing Industrial

FG-200 Version V1.21

The primary feature of version V1.21 of the FG-200 gateway is upgraded communication reliability between Ethernet devices. In particular, it has been geared towards the modern industrial environment, filled with interfering signals that tend to disrupt communication along lengthy Ethernet cabling. With better methods of removing interference than the previous version, communication is faster and fewer dropped or repeated packets are necessary. Besides the communication upgrade, Softing has also updated the FG-200’s firmware functions to be more intuitive and reliable.

The FG-200 is designed to be future-proof. It is expected to last through many years of service without becoming obsolete. Long-term usability makes it an ideal candidate for replacing legacy devices in evolving manufacturing and industrial facilities.

Process Automation and Beyond

The FG-200 is designed to handle the demands of instrumentation and control systems in the oil and gas industry. Long cable lengths, electrically noisy environments, and the need for long-term solutions dominate the oil and gas market sector. The ability to wire these devices in an intrinsically safe protocol, like FF H1, meets the needs of these markets by limiting the chances of electrical sparks igniting flammable vapors.

Even so, many industries will benefit from the FG-200 outside of oil and gas, including large manufacturing facilities. The pharmaceutical and semiconductor industries, with many pieces of quality control hardware (and thus their electrical noise), will also find the FG-200 a useful addition. Overall, any industry concerned about having to repurchase and replace legacy hardware every few years, or any industry that has had their communication slowed by interference, will appreciate Softing’s Foundation FG-200 gateway.