ABB and Red Hat are expanding their collaboration to bridge the long-standing divide between IT and OT. By integrating Red Hat’s OpenShift and Device Edge into both the digital and control layers of ABB’s industrial systems, the partnership allows manufacturers to adopt cloud-native, AI-driven, and edge computing technologies without disrupting core operations. The layered architecture offers a safer, modular path to modernization, ensuring innovation without compromise.

ABB’s process automation systems will now feature Red Hat’s open source platforms, such as Device Edge. Image used courtesy of ABB

Process industries such as those that are involved with energy, chemicals, and manufacturing rely on tightly controlled environments to ensure safety and performance. But as the digital world races ahead with AI, edge computing, and cloud platforms, these legacy systems are often left behind, stuck between the need to modernize and the risk of disrupting critical processes.

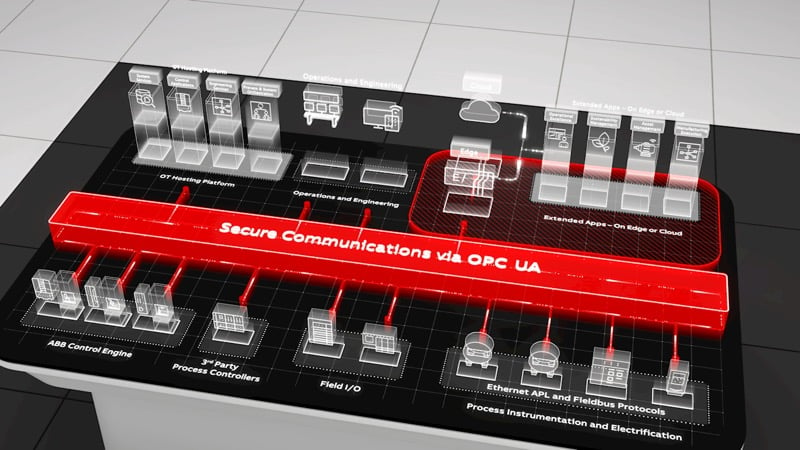

To tackle these challenges, ABB and Red Hat are joining forces in a manner fitting for how industrial systems work in the real world. Instead of forcing companies to overhaul everything at once, they’re introducing a layered approach, where one part focuses on the core control systems that keep things running, and another that handles new tech like AI, analytics, and cloud tools. It’s not just about adding more software; it’s about making it easier to try out and roll in new capabilities without risking the stability of what's already working. And because it’s built on Red Hat’s open-source platforms, it gives manufacturers more flexibility, more control, and a much smoother path toward modernizing over time, without starting from scratch.

A Joint Venture To Ensure Industrial Transformation.

The collaboration now covers both the digital and control environments of ABB’s automation architecture. Previously, Red Hat’s platforms, like OpenShift, were used to enable flexible deployment of AI and cloud-native tools. With the latest extension, Red Hat’s technology will also anchor the control layer, the part of the system responsible for managing critical, real-time operations. This is a big deal. It means that industries can now incrementally adopt new tech without tearing down what’s already working.

What Red Hat Brings to the Table

So, what exactly are these Red Hat tools making this possible? For those unfamiliar, two products are doing most of the heavy lifting: Red Hat OpenShift and Red Hat Device Edge.

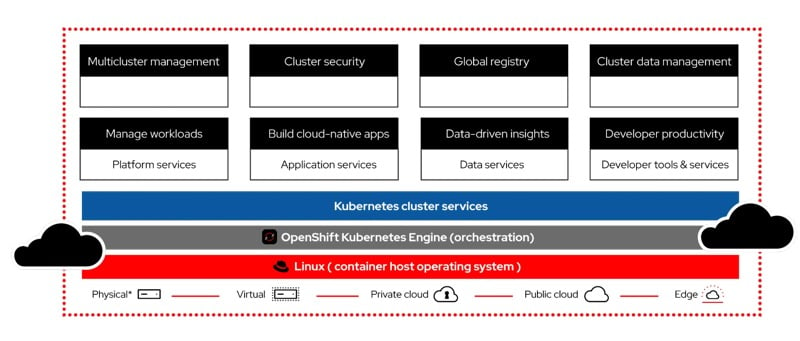

ABB’s customers will be able to utilize OpenShift to develop and deploy their own apps. Image used courtesy of Red Hat

Red Hat OpenShift is a platform that helps developers create and manage applications at scale. It’s built on Kubernetes, an open-source engine for managing containers, or packages of software, but with enterprise-grade bells and whistles. Essentially, it provides automated security checks, continuous integration tools, and flexible deployment across cloud, on-prem, or hybrid setups. OpenShift gives industrial teams the ability to roll out new applications, like AI models that detect pump failures, without reinventing their entire system.

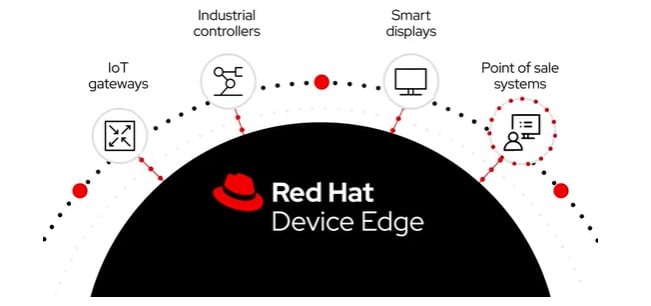

Device Edge can be used to handle different workloads, no matter where they are deployed. Image used courtesy of Red Hat

Red Hat Device Edge, the lesser-known sibling, plays a different but equally vital role. Industrial operations often involve machines in remote locations with limited computing power and spotty connectivity. That’s where Device Edge excels. It offers a slimmed-down, edge-optimized version of Red Hat Enterprise Linux, coupled with MicroShift, a lightweight Kubernetes engine tailored for low-resource, hard-to-reach devices. It’s like having a smart operating system baked into a field sensor.

From Core to Edge: Consistency at Scale

What makes this especially powerful is the consistency it brings from core to edge. Red Hat’s platforms allow businesses to manage thousands of remote devices using centralized tools. They can push software updates, automate rollouts, and even control configurations through Git repositories, which is a method traditionally used in software development, now applied to industrial infrastructure. For companies that may have limited on-site technical support, this model can be transformative, as it reduces the need for physical maintenance, cuts downtime, and improves resilience against cybersecurity threats.

Modernizing legacy industrial systems without compromising their reliability can be extremely challenging, especially in systems that may not have had the best maintenance records. By combining ABB’s control expertise with Red Hat’s modular, open-source platforms, the two companies are combining innovation with stability, which can turn a long-standing trifling industrial dilemma into a real opportunity.