ABB is leveraging generative AI in two jointly developed, newly available solutions, the ABB Industrial Knowledge Vault and ABB My Measurement Assistant+. Featuring the Genix Copilot GenAI assistant and Microsoft Azure OpenAI Service, the technologies are designed to invigorate workforce training and maintenance capabilities through natural language-led training, guidance, analytics, and insight generation. The two solutions are intended to help grow and retain the future industrial workforce, optimize productivity, reduce maintenance costs, and maintain business continuity.

Using GenAI can help augment employee skills and training, speeding up data retrieval and analytics to inform decision-making for rapid, downtime-reducing operations. Image used courtesy of ABB

Tackling the Talent Conundrum

We’re all familiar with the crippling manufacturing workforce shortage pervading the U.S. and other key markets in countries across the globe. The problem that many manufacturers and businesses are facing is the loss of older, more experienced workers with skills and knowledge that ensure maximum operational efficiency and productivity. Further, the younger generation that would make up the future industrial workforce is susceptible to job application inertia when considering flexible working, whether the job is within an amenable commuting distance, whether the job adds value and aligns with a worthwhile purpose, whether they employ all or a majority of advanced skills and qualities (that change rapidly with further advances in control systems, robotics, and automation technologies), and what career progression they may or may not experience in the light of increasingly automated workflows and processes.

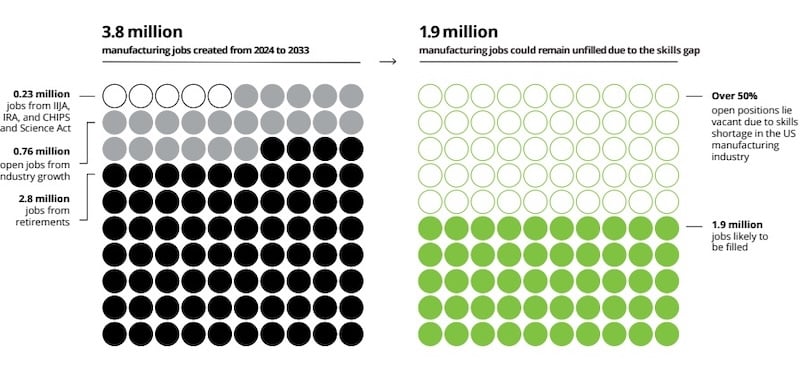

A graphic depicting the results of Deloitte’s analysis of data from the U.S. Bureau of Labor Statistics and private investments from invest.gov. Image used courtesy of The Manufacturing Institute

According to Delloite’s 2023 Workforce Experience study, employees who believe they can gain the required skills for future career progression are 2.7 times less likely to move on to another job in 12 months. Companies are focusing on a skills-based approach to employee retention and continued growth, focusing on the qualities and abilities of applicants, rather than role titles and qualifications. According to Deloitte, manufacturers are focusing on developing digital, soft, and technical skills amongst their employees. Onboarding digital technologies requires soft skills such as critical thinking, problem-solving, adaptability, initiative, and leadership to handle complications, optimization, and continued productivity.

Other insights from Deloitte reported an industrial workforce of more than 270,000 machinery maintenance technicians in 2022, with the figure projected to increase by 16% by 2032.

ABB Ability Industrial Knowledge Vault

ABB announced the release of its employee-focused, generative-AI led ABB Ability Industrial Knowledge Vault, designed to empower employees through maximizing accessibility to accumulated skills and knowledge from the work of past and present employees. Jointly developed by ABB and Microsoft, the knowledge platform leverages Microsoft Azure OpenAI Service and ABB Genix CoPilot to store and maintain skills and knowledge, and analyze data, generating actionable insights for improving industrial operations. Engineers and operators can benefit from the expedience of natural language conversations, which lead to immediate, organized procedure generation to execute tasks efficiently.

The Knowledge Vault solution uses AI to extract information based on natural language inputs, analyze workflow data, review, and optimize instructional outputs (by referencing real-world workflow scenarios) to achieve the business's gold standards.

Employee retention and bridging the skills gap are key issues facing the manufacturing industry. The Industrial Knowledge Vault from ABB is intended to solve these issues through dedicated tribal knowledge storage and access. Video used courtesy of ABB

This system provides a set of digital resources for managing and streamlining facility operations. The Document Repository is a safe, user-friendly location to store and retrieve critical documents. Genix Copilot allows customers to communicate with system operations and machinery in simple, natural language. Through an intuitive drag-and-drop interface, Procedure Manager enables customers to create and modify workflows. At the same time, Policy Management maintains the consistency and security of procedures by managing iterations and limiting access.

Additionally, the platform improves team supervision and coordination. By assigning and monitoring activities that are closely related to predefined processes, Task Manager facilitates real-time engagement with field personnel. By providing immediate insights into operations and workflows, the Overview Dashboard enhances overall productivity and helps avoid delays. Employees may access processes from a smartphone or tablet by using the web client and mobile app. Protection against cyber attacks is ensured by ABB Cyber Security's use of industry-standard, tiered security procedures based on NIST 800-53.

ABB My Measurement Assistant+

ABB’s My Measurement Assistant+ is another industry-leading solution born from collaboration with Microsoft. The solution provides a mobile-accessible, instant access point to machine data, diagnostics, and expert-guided remote support to help customers resolve issues remotely, with greater speed, and with minimal downtime. The Measurement Assistant+ is the first Gen-AI-backed solution of its kind, allowing engineers and technicians to access professional guidance, video tutorials, and troubleshooting guides remotely or at the direct source in the field.

ABB promotes mobility and agility within industrial maintenance teams through the provision of a Gen-AI-backed, remote, technical support solution. Video used courtesy of ABB

ABB's Condition Monitoring, Genix Datalyzer, and Dynamic QR Codes combine essential insights in a central hub to facilitate faster and more straightforward decision-making. Without having to hunt, engineers may quickly access a device's diagnostics, condition report, and pertinent information by scanning its QR code with a smartphone.

Teams can swiftly identify and resolve problems with the help of Genix Datalyzer's extensive root cause analysis feature, which is supported by real-time data coming into the platform. It's a useful, effective method of monitoring the effectiveness of assets and cutting down on unscheduled downtime.

Securing and Enabling the Future Workforce

Overall, ABB and Microsoft’s jointly developed technologies are an answer to the filling of jobs and the skills gap left by highly experienced senior workers. Using ABB Ability’s Industrial Knowledge Vault as an invaluable tribal knowledge store bolsters training, empowers employees, all the while lowering training costs and bridging the skills gap. The inclusion of GenAI makes learning conversational and self-guided, and allows employers to provide individual, tailored training to suit their existing skills and capabilities. This worker-centric approach to development and career progression is likely to strengthen employee retention. Employers can also focus more on hiring applicants based on existing skills and qualities, which is expected to tackle job application/applicant inertia and help tackle the labor shortage in manufacturing.

Featured image used courtesy of ABB