A leader in digital solutions for robot-driven manufacturing, Flexxbotics has recently announced a new robotic compatibility level with LMI Technologies’s comprehensive suite of inspection products and 3D measurement solutions. This advanced compatibility with robotic machine tending enables the company to support high-precision quality inspection capabilities through closed-loop quality control and full autonomy in smart manufacturing environments.

Quality Control with FlexxCORE Technology

At the heart of Flexxbotics’s new solution is its FlexxCORE technology, a platform that coordinates and connects production robots with LMI Technologies’s advanced inspection tools, allowing for real-time feedback and adjustments. As the robots carry out their tasks, the integrated solution allows for the continuous collection of inspection data, enabling CNC machine programs to be autonomously adjusted based on the inspection results. By automating quality checks, robots can make adjustments in real-time, maintaining Six Sigma consistency.

Flexxbotics now offers compatibility with the entire range of LMI Technologies’s advanced inspection and 3D scanning equipment, including the Gocator 3D Sensors, such as 3D snapshot sensors, 3D line confocal sensors, 3D point profilers, and 3D line profilers. The FocalSpec 3D line confocal and the Chroma + Scan multipoint scanners also form the LMI Technologies compatible line-up for feature detection and high surface profiling.

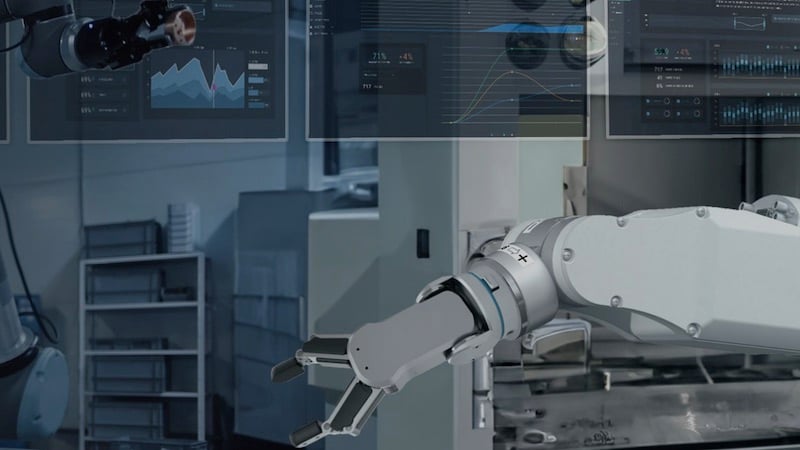

Integration with the LMI Technologies sensory data and tools offers real-time feedback and adaptation for robotics. Image used courtesy of Flexxbotics

The new compatibility platform also features seamless integration with various inspection tools, including vision systems, probes, lasers, and coordinate measuring machines (CMMs). Seamlessly integrating with existing manufacturing systems, including SCADA, CAD/CAM, IIoT, DNC, MES, PLM, and ERP platforms, significantly reduces the cost of overhaul. The broad compatibility reduces the need to set up new structures, allowing the system to be built on existing inspection technologies.

Advantages for Modern Manufacturers

With the new compatibility by Flexxbotics, manufacturers can significantly reduce defects, improve throughput, and achieve seamless integration of inspection tools and robots. Through autonomous orchestration of inspection of workflow and production robots, the Flexxbotics system helps smart factories increase efficiency and profit per part.

3D LMI Technologies compatibility allows for autonomous and precision-driven manufacturing. Image used courtesy of Flexxbotics

The solution features bi-directional communication, allowing for real-time data exchange and enabling robots to receive feedback, update parameters, and issue commands to inspection devices. According to the CEO and Co-founder of Flexxbotics, Tyler Bouchard, who highlighted the potential of the new solution to transform smart factory operations, closed-loop quality control will allow CNC and other assets in the industry to operate continuously for higher yields. In addition to autonomous and real-time process control, Flexxbotics' new solution features an online and offline functionality that ensures that production is uninterrupted even without access to the internet.

The Future of Robot-Driven Manufacturing

The compatibility between Flexxbotics and LMI Technologies’s equipment represents a significant step in the industry’s shift towards robot-driven and autonomous manufacturing. As echoed by Flexxbotics’s CTO and Co-founder, Tyler Modelski, the solution aligns with the company’s goal to offer seamless integration for high efficiency and quality levels. With the growing demand for precision and efficiency in manufacturing, Flexxbotics's compatibility solution redefines production control standards and quality inspections for more efficient smart factory operations.