Patlite has released a new series of signal lights that can be quickly configured for any piece of industrial equipment that has a PLC or industrial PC at its core. The LR5-LAN signal tower series is made to be directly interfaced instead of being routed through an output contact board. By eliminating this extra component, configuration is simplified.

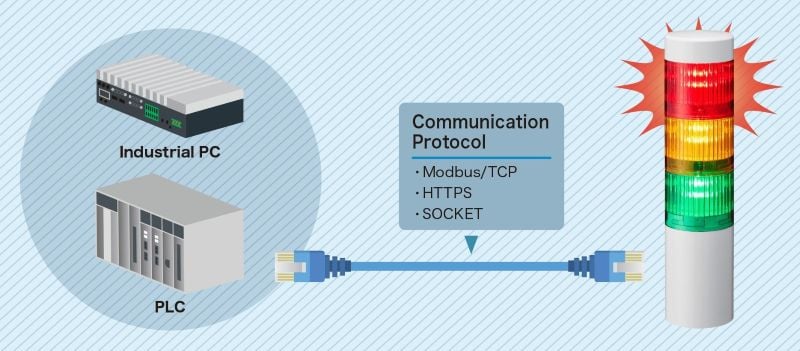

The new LR5-LAN signal tower series can be controlled from either a PLC or industrial PC over several common protocols. Image used courtesy of Patlite

LR5-LAN Signal Tower Series

The LR5-LAN signal tower series is available in several configurations. All have lights that are visible from 360° around the tower, making it easy to see the tower from all sides. Furthermore, the lights are in a standardized position (red, yellow, green, and optional blue and white), meaning that even technicians experiencing colorblindness can understand the status of the machine at any time.

Each tower uses LED lights for extended lifetime and can be powered by 24 V DC lines or an optional 110 V AC adaptor, making it versatile and simple to set up.

Ease of Configuration

Without the need for an output contact board, the LR5-LAN signal tower can be quickly installed and configured. The output from a PLC or industrial PC can be connected to the LR5-LAN with an Ethernet cable, which allows communication via Modbus/TCP, HTTPS, or SOCKET protocols.

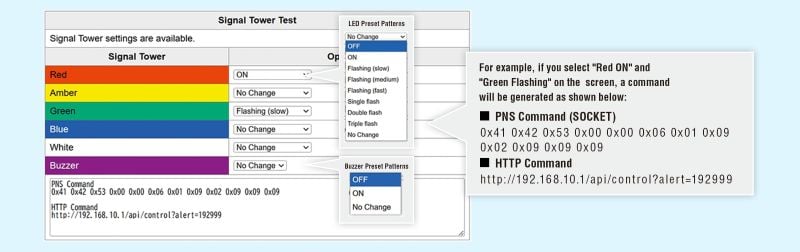

An intuitive software interface enables users to define the criteria for signaling: which color light will illuminate and whether it will flash in a pattern. Patterns include single, double, and triple flashes, as well as slow, medium, and fast continuous flashing speeds. Some models also have an audible alarm (85 dB) that can be programmed for critical errors. Sample code is available from the Patlite website as well.

The LR5-LAN can be configured via intuitive software so users can set which color light illuminates and in what pattern. Image used courtesy of Patlite

A Simplified Signaling Solution

Signal lights are commonly used in large manufacturing environments, such as in semiconductor facilities. When multiple pieces of processing equipment are in use simultaneously, a maintenance technician can simply look down the bay or chase and check the status of all of the signal lights. If they are all green, the technician can move on to the next bay or chase. At a glance, they know exactly which tools need attention and can reduce the time it takes to respond to errors, as well as reduce the number of steps they have to take in a shift.

Semiconductor manufacturing facilities make use of signal lights to speed up troubleshooting and maintenance. Image used courtesy of Patlite

Expanding beyond semiconductor manufacturing, virtually any machine tool or piece of process equipment can be quickly integrated with the Patlite signal towers. For a robotic machining operation, the lights could be programmed to handle specific errors, such as light curtain intrusions, welding spools needing replacement, and other such problems.

Overall, the Patlite signal tower’s main market is large machining and manufacturing operations where tools and process equipment are plentiful. The ability to monitor multiple machines at a glance will save time and troubleshooting efforts.